SAND MANAGEMENT services

FOR

Early Production

Meet your desanding needs while minimizing cost by combining cyclonic and filtration sand management technologies customized for your application.

How are you managing the potential for sand damage during the early stages of your well’s life?

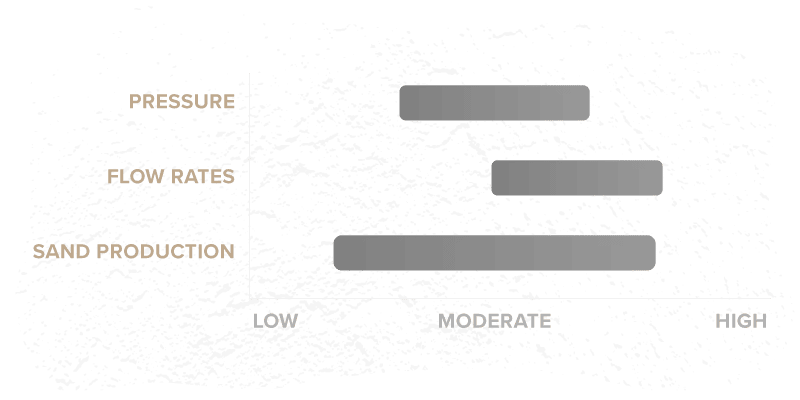

The early production phase stretches from the second month that your well is flowing to the end of the first year. While the pressure is declining, there is still a strong potential for sand production and subsequent damage.

With a variety of skid-based desanding offerings for this phase and your unique application, EnerCorp can meet your sand management needs while minimizing HSE exposure and personnel requirements.

We offer a number of technology solutions and service options. Our experienced team can:

Offer a range of sand management solutions to address persistent solids production

Mitigate sand issues on your well after being hit by an offset frac

Implement remote monitoring and automation technologies to give real-time visibility of site conditions

Prepare reports for production related metrics

Support field logistics for sand management equipment with your lease operators

Check your facility on a daily or weekly basis

Revolutionize the early production and flowback phase of your well with a fully autonomous solution

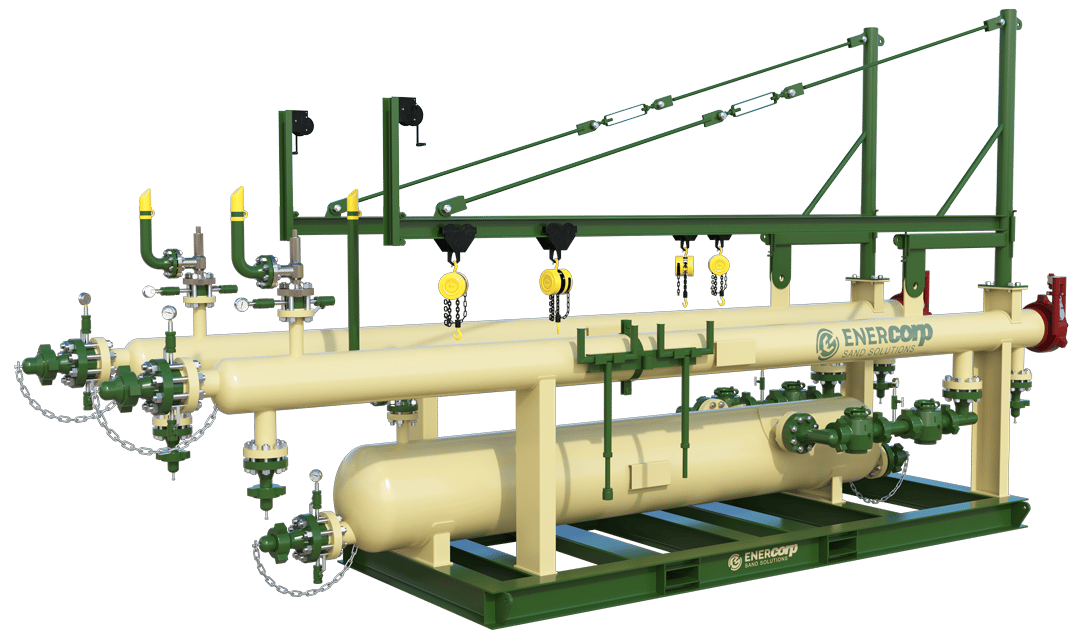

With a multitude of production skid configurations, we are ready to service your wells

World-class sand separation capture rate >97%

Highly accurate weight measurement connected to SCADA for operator call-out only when needed

Blowdown vessel fluid removal and recycling system eliminates extra trucking and disposal costs due to liquid

Blowdown vessel sand volume is monitored and connected to SCADA for disposal truck call-out only when needed

Self contained blowdown limits HSE exposure – potential for full closed loop system

Why is sand management important during early production?

Desanding issues make a big operational impact

Reduce costs from replacing parts and cleaning out vessels or tanks

Minimize non-productive time and lost production due to shutting in wells

Eliminate environmental release incidents and clean up costs from washed out parts

Lower HSE exposure and emissions due to opening vessels or tanks

Our team of engineers and sales professionals are standing by to discuss your well.

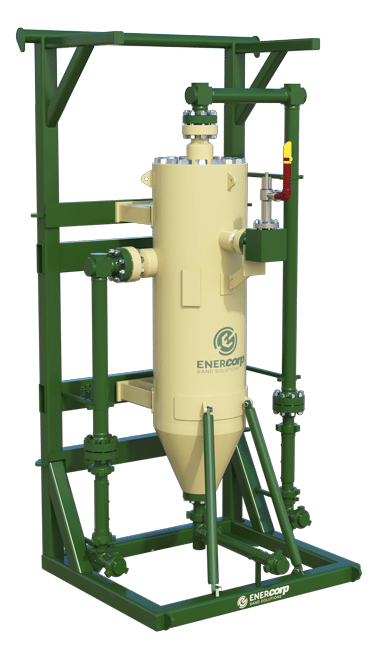

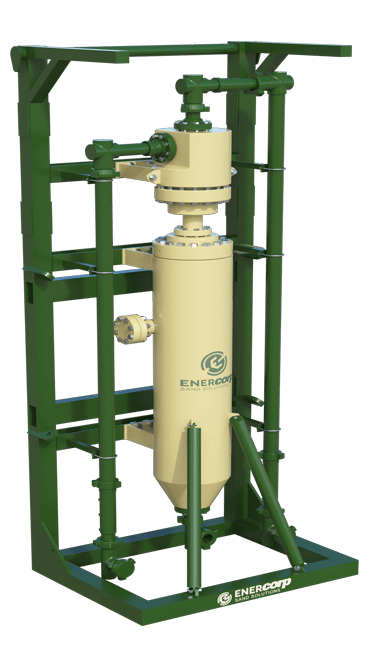

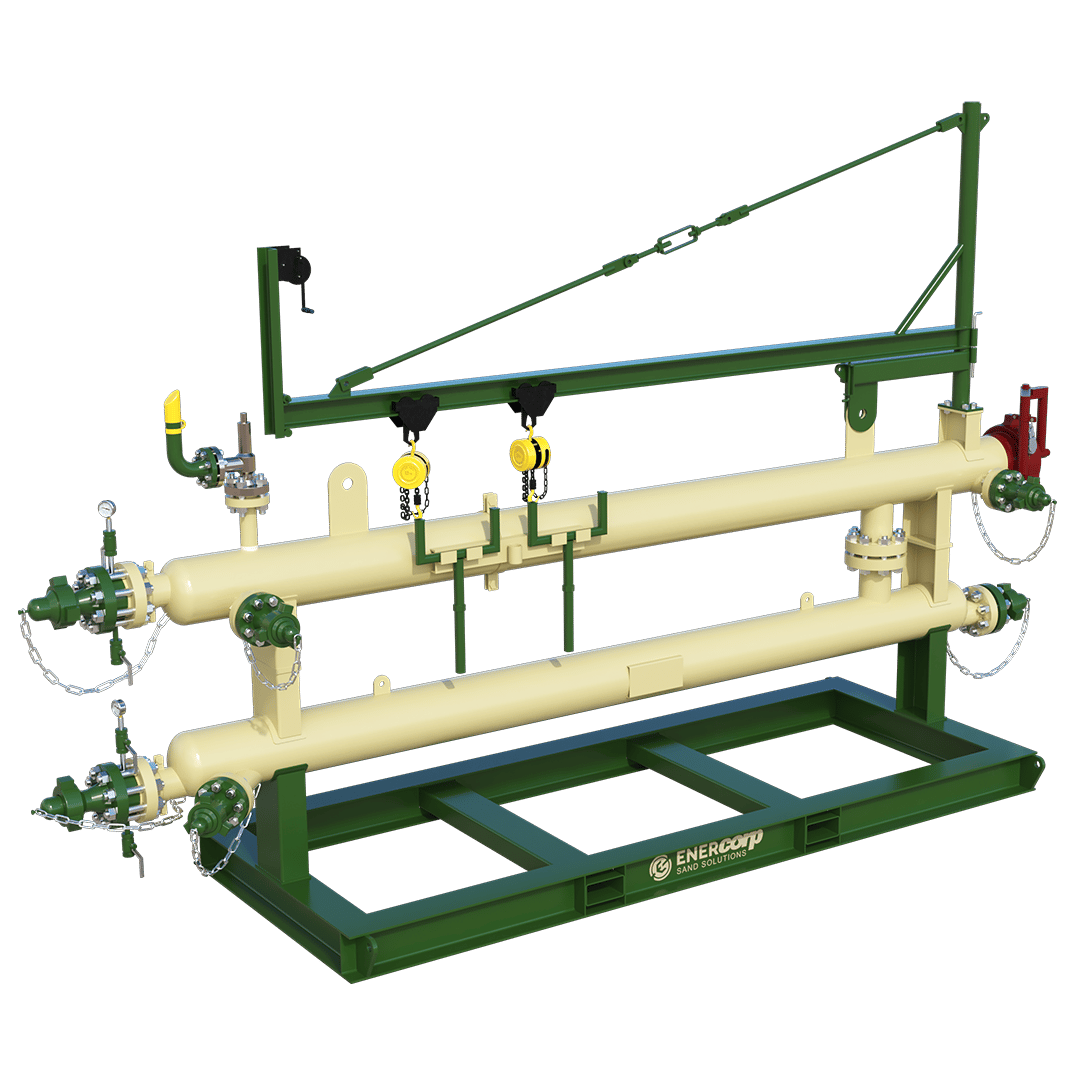

Sand Separation Options

Cyclones

Filters

A combination of both cyclones & filters

Sand Cyclones

BOE per day

Sand Filters

Sand Capture Rate

Popular Production Skid Add-On Features

Digital Sensors & SCADA

- Pressure monitoring for filters

- Weight monitoring for cyclones

- Volume monitoring for blowdown vessels

Objective: deploy personnel only when needed

Blowdown Vessels

Fully contained vessel that can be tied in to onsite flare if needed

Objective: zero environmental or personnel exposure

Blowdown fluid recirculation system

Pump down the fluid in the blowdown vessel and reinject it back into the production stream

Objective: Significantly reduce the volume of vacuum trucks needed to dispose of sand and liquids waste from the blowdown vessel

Arctic Package

Winterize the unit to withstand harsh cold temperatures

Objective: eliminate downtime in winter