or one of the other guys?

Is your flowback service provider a leader in sand management — or are they using generic solutions that aren’t optimized for your wellsite?

Download How To Tell If You’re Working With a Leader in Sand Management and find out if it’s time to look for a new partnership.

At EnerCorp, we’re not satisfied with standing still. We’re constantly researching and developing ways to enhance operations for our customers, saving them time, money, and effort.

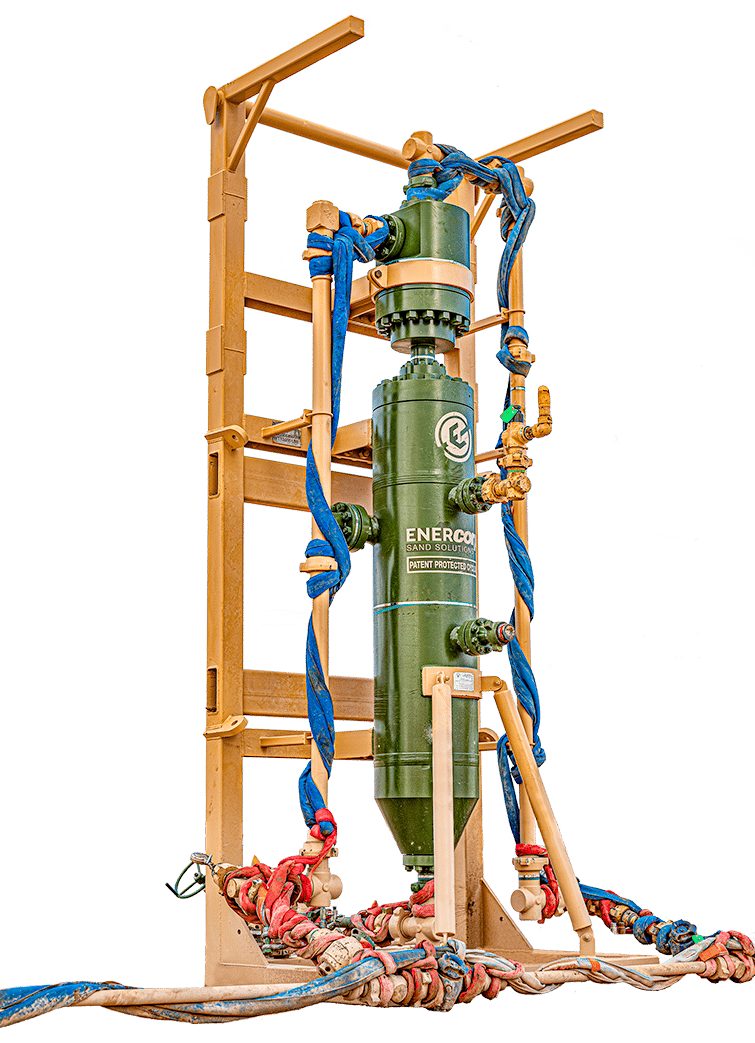

We pioneered the industry-leading Sahara Sand Cyclone, with a 97% sand capture rate.

We were first to develop an effective autonomous flowback and sand management ecosystem, eFlowback.

We’re now revolutionizing the multiphase flow measurement industry, applying cutting-edge electromagnetic imaging technologies that provide high-speed measurements in real time.

See where we’ll take the industry next.

Each stage of the well’s lifecycle is in good hands with EnerCorp

Flowback

and well testing

Highly engineered solutions using premium materials that eliminate non-productive time.

Sand management solutions

Innovative cyclonic and filtration-based desanding technologies that remove more sand than anything else on the market.

Production equipment fabrication

Rigorously tested and engineered custom equipment for sand management and production processing.

Our proven process ensures we meet your well’s requirements

Ready to start step 1?

Click the button below to reach our sales team today.

We understand your well’s unique requirements:

Our sales and engineering teams analyze your expected oil, water, and gas rates, as well as your pressures and sand loading metrics.

We offer a range of fit-for-purpose solutions:

There are a number of different ways you can reach your goals. We show you how with 2-3 optimized equipment layouts utilizing only what you need.

We bring the plans to life:

Once we’ve determined the best solution for your well, our highly trained field service personnel rig up the site and expertly operate the equipment so you have peace of mind.

We quantify results to drive ROI:

If you want to maximize your well’s financial return now and in the future, numbers matter. We provide detailed results throughout the process so you know how your wellsite is doing at all times, and we perform post-well analysis to drive optimization for the next job.