The job site of the future is here

Five years ago, a completely autonomous job site for flowback was unthinkable. Today, it is a revolutionary reality.

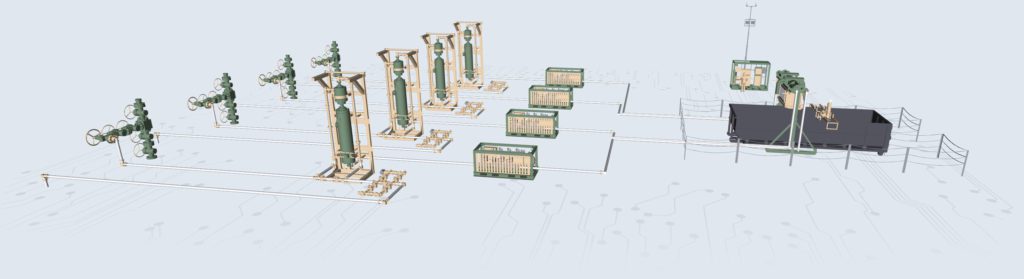

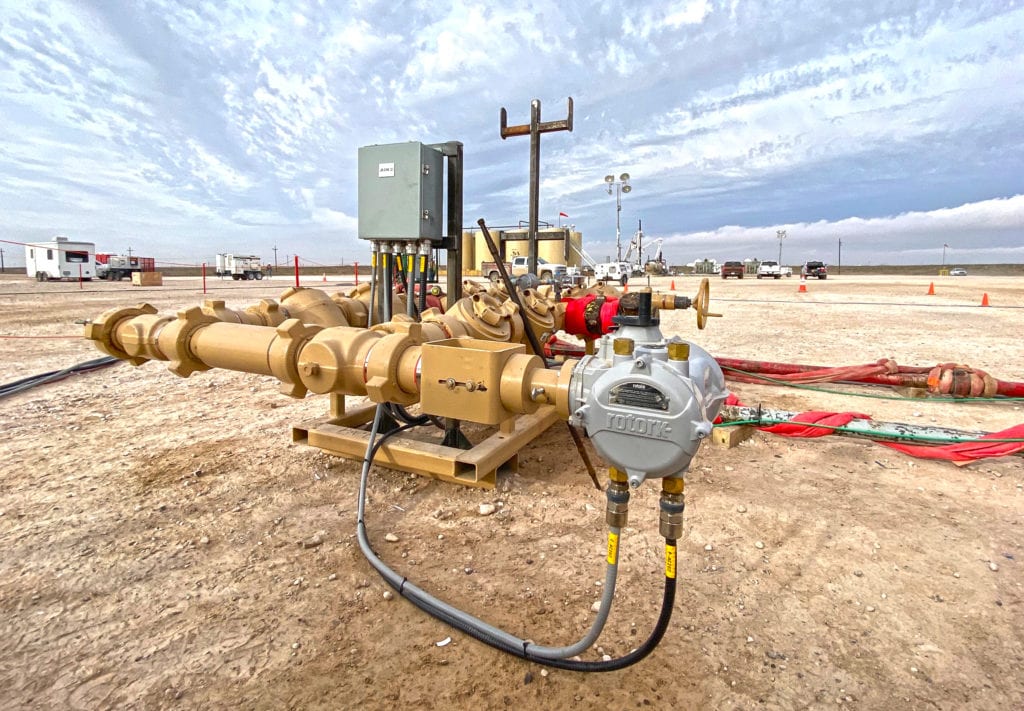

Traditional flowback and sand management operations involve very little technology. Most service providers only offer commodity equipment that is not highly engineered and doesn’t fully clean up solids from the well’s production. This ineffective desanding results in expensive damages to equipment and the production facility.

Historically, site setups include a lot of equipment and a large amount of personnel on location to provide service. Exploration and production operators deal with increased emissions from this inefficient setup while paying exorbitant daily rental costs and labor costs when there is a better way.

Introducing EnerCorp’s eFlowback technology

Reduces excess equipment

Lowers labor costs

Lowers flowback expenses

Reduces HSE exposure

Cleaner production facilities

Lowers emissions

EnerCorp puts the E in eFlowback, taking flowback forward

ECONOMICAL

Environmentally friendly

Efficient

Exceptionally safe

Enables enhanced decision making

More than just point solutions

eFlowback is an entire digital flowback ecosystem

The benefits of eFlowback vs. traditional flowback are clear

REDUCE HUMAN AND ENVIRONMENTAL EXPOSURE ON LOCATION:

DELIVER INDUSTRY-LEADING SAND CAPTURE EFFICIENCY:

PROVIDE CONSISTENT AND RELIABLE SERVICE:

ENHANCE ACCESS TO DATA AND ANALYTICS:

RECEIVE INDUSTRY-LEADING VALUE FOR SAND MANAGEMENT SERVICES:

Enter the job site of the future with eFlowback today

Feel like your flowback operations are stuck in the previous century?

That’s because there are a lot of inefficiencies in traditional flowback processes. Hauling out a large amount of excess equipment to the wellsite along with multiple personnel — without regard for well conditions and flow rates — is not an effective way to manage flowback operations.

If you want to take flowback forward, it’s time to explore eFlowback with EnerCorp.

Download 5 Ways to Take Flowback Forward with eFlowback today and learn how you can enhance your operations at the wellsite while reducing your equipment footprint, personnel costs, and environmental impact.

Will our claims that eFlowback reduces methane emissions stand up to an independent third-party study?

At EnerCorp, we believe in always backing up our word with data. It’s not enough for us to tell you that eFlowback minimizes methane emissions as compared to standard sand knockouts — we wanted to show you the hard evidence.

Read the results of the study below and learn just how much we can minimize environmental impact with our technology, and how we’re moving the industry forward as a whole.