A step change in emissions: eFlowback

Estimated reading time: 4 minutes

Environment, social, and governance (ESG) initiatives have been at the center of focus in the oilfield industry for the past several years. From investors to customers to the public, everyone is interested in ways oil and gas companies can enhance their ESG programs. At EnerCorp, ESG has been a focus long before it was a buzzword. Our innovative Sahara Advanced Sand Cyclone, which has a sand capture rate of over 97%, has been designed with ESG initiatives in mind. Not only does it make flowback cost effective and efficient, but the Sahara also provides a solution to minimize the environmental impact of our industry.

As part of the autonomous flowback system, eFlowback, the Sahara enables operators to minimize emissions while reducing equipment and personnel costs. In this blog post, we’ll take you through the numbers and show you exactly the kind of impact eFlowback has on the environment when compared to other flowback and sand management systems. Plus, we’ll also share how EnerCorp is pushing the industry forward in terms of ESG initiatives.

Table of contents

Third-party emissions study with outstanding results

It’s important for us to back up every claim we make. That’s why EnerCorp brought in an independent third-party to conduct an emissions study on our eFlowback system to ensure that it was indeed providing our customers with environmental benefits when compared with traditional sand knockout flowback systems (also known here as flowback 1.0).

Our engineering team studied different types of equipment used in flowback to identify the measurement requirements for emissions. Our goal in the study was to determine the emissions profile of our eFlowback equipment as compared to other systems on the market.

Through this study, we were able to validate our engineering design features of the Sahara Advanced Sand Cyclone, a critical component of eFlowback, and show that it produced far less emissions than standard systems.

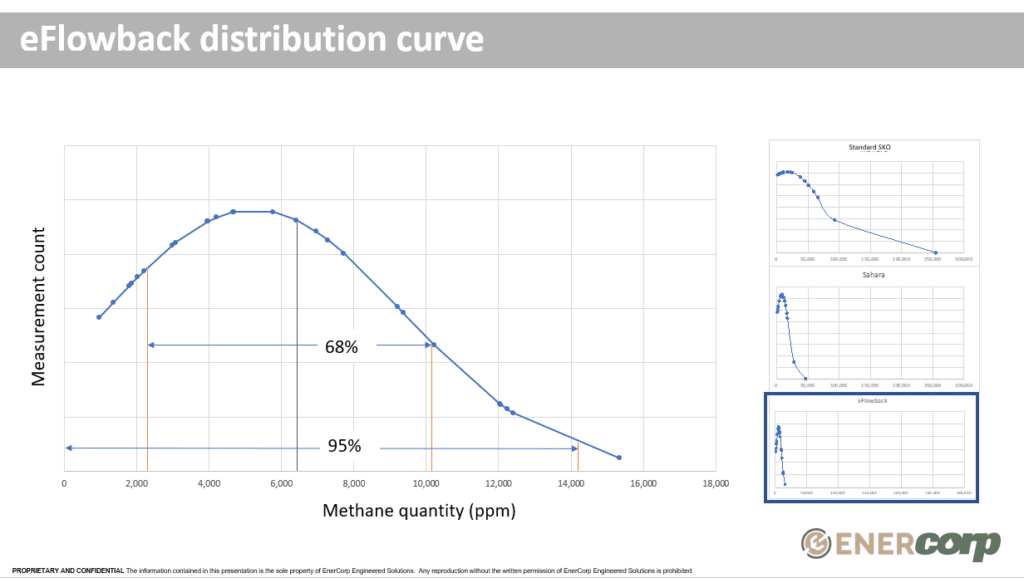

eFlowback further reduces emissions on flowback jobs by providing automation controlled consistency. Blowdowns can be tuned to only blowdown the minimum volume necessary to evacuate the sand and guarantee that the vessel never “gasses out”.

During the third-party study, the team measured the detection of the following elements using a three-point probe:

- nitrous oxide (N2O)

- methane (CH4)

- selected hydrocarbons (HCs)

- carbon dioxide (CO₂)

- oxygen (O₂)

The conclusions of this study were eye-opening to say the least. Here’s what the third-party determined:

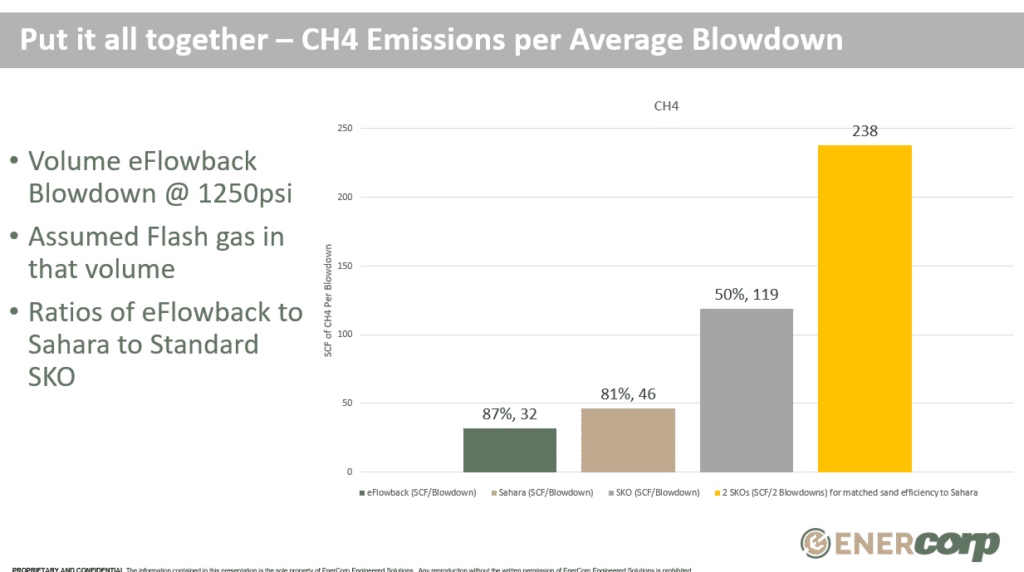

- Methane is the largest component measured by the 3-point probe in all cases

- The Sahara produces 81% less emissions than a standard sand knockout per blowdown

- eFlowback produces 87% less emissions than a standard sand knockout per blowdown

- When comparing based on equivalent sand capture performance (2 standard sand knockouts = 1 Sahara) these ratios are doubled on a per blowdown basis

Taking the industry forward for emissions reduction

While the third-party study showed the efficacy of our technology when it comes to emissions reduction, we wanted to take things a step further. After all, it’s not enough for just one service provider to improve their emissions. The real difference happens when the entire industry does it.

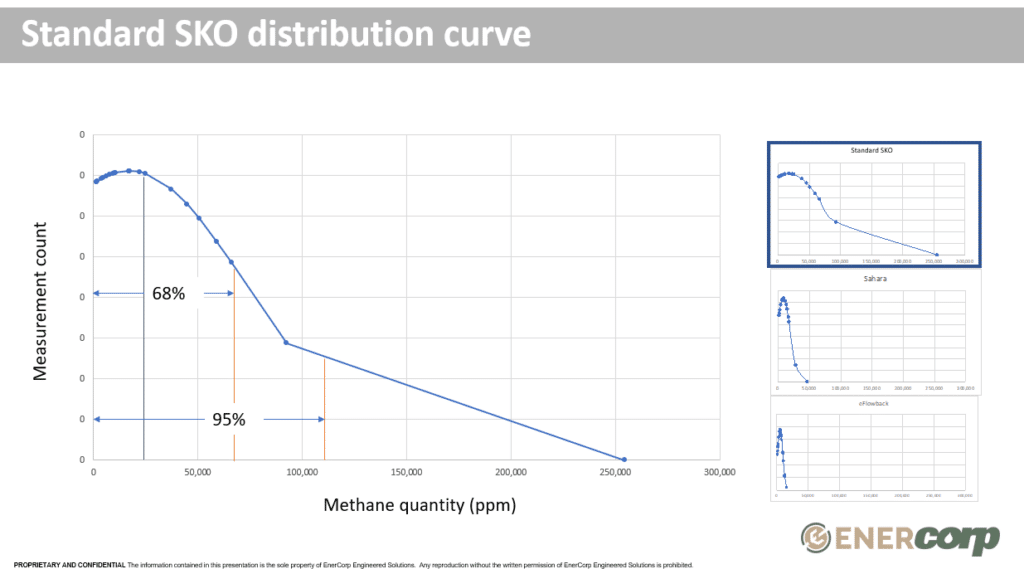

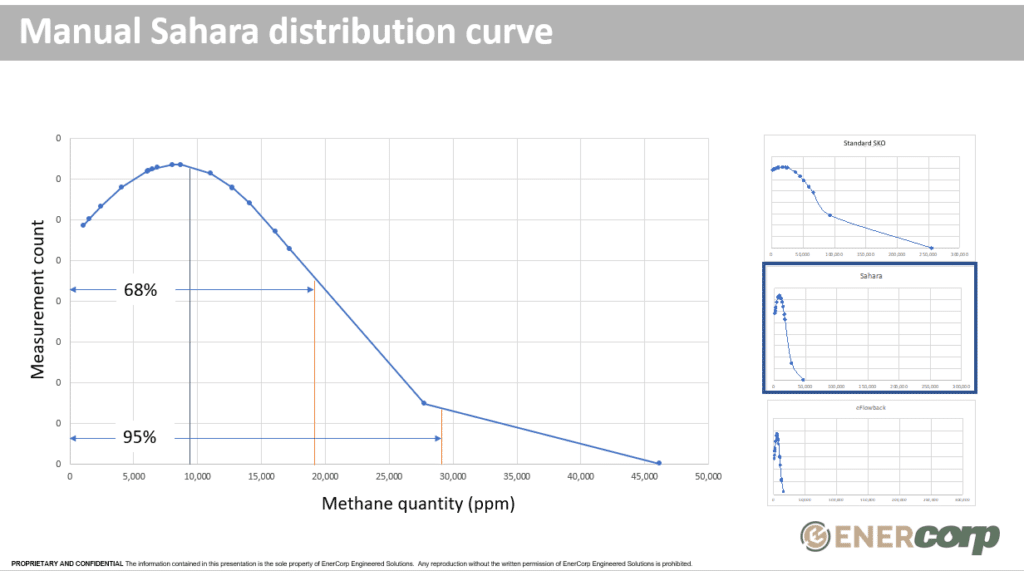

Combining all the data from the study, as well as the data from our process simulation using computational fluids dynamics (CFD), process simulation software, and real historical data collected with our eFlowback automation, we were able to determine the unique EnerCorp emission signature profile for eFlowback, manual Sahara, and competitor sand knockouts. Using this, we developed a comprehensive emission calculation based on EPA standards and open source literature for emissions quantification. The EnerCorp emission signature was input to this framework to show the emission profile for a different type of equipment.

With the open source literature to establish and calculate the emissions, other companies can use this and adopt it to their emission signature — helping them figure out how best to innovate their technology to reduce emissions.

The future of the oil and gas industry is going in a new direction with ESG

Over the last decade, the oil and gas industry has changed considerably. Take a look at how far the Sahara Advanced Sand Cyclone has come as compared to a standard sand knockout. EnerCorp is committed to being at the forefront of innovation, leading the industry to create more effective technology that serves our customers and creates a better future for everyone.

We encourage other service providers in the industry to track their emissions and work towards reducing them through equipment innovations. But more importantly, we encourage our team to continue their research and development of industry-leading technology that moves everyone forward.

To learn more about our third-party study, our emissions profile, or our ESG initiatives, get in touch with EnerCorp today.

Share this Article