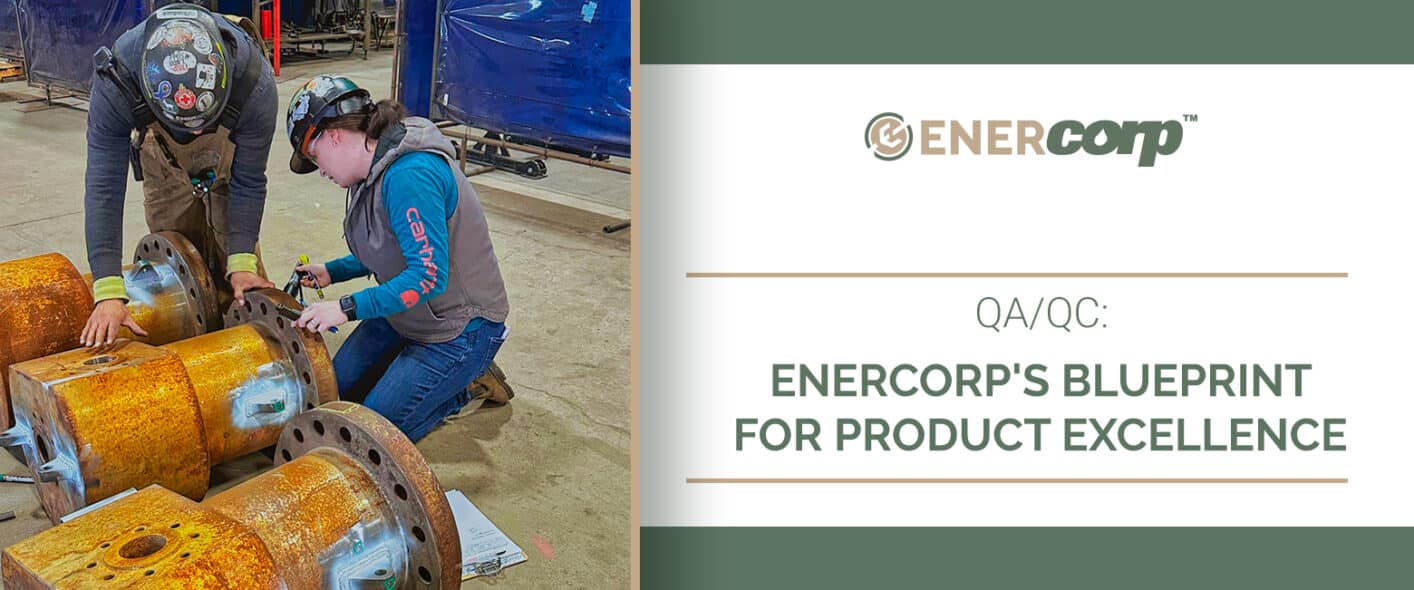

At EnerCorp, we understand that when it comes to fabricating equipment, there’s no room for compromise. That’s why we’re unwavering in our commitment to QA/QC at every step of the process.

Here's why it matters:

- 1Safety First: QA/QC ensures that the equipment we build is not only functional but also safe. Your peace of mind and the safety of your team are our top priorities.

- 2Reliability: Our rigorous QA/QC processes guarantee that our products meet or exceed industry standards. You can rely on our equipment to perform consistently and efficiently, reducing downtime and increasing productivity.

- 3Longevity: When it comes to your investment, we're in it for the long haul. Our QA/QC procedures ensure that our equipment is built to last, saving you time and money in the long run.

- 4Compliance: We stay up-to-date with the latest regulations and standards to ensure our equipment is fully compliant. You can trust that your projects will meet all necessary requirements.

- 5Customer Satisfaction: Our commitment to QA/QC is a commitment to your satisfaction. We take pride in delivering products that not only meet but exceed your expectations.

So, when you choose EnerCorp for your desanding product needs, you're getting people like Laura Schmitke and Nicole Allan who care deeply about the items listed above. Quality isn’t something we do, it’s who we are at our core.

Learn more about Production Equipment Fabrication at EnerCorp

Share this Post