SAND MANAGEMENT services FOR

Steady State Production

Just because your well has been flowing for over a year doesn’t mean the risk of sand production is gone

The steady state production phase begins at the end of the first year the well is online and lasts until the end of that well’s life. However, although the well’s production and pressure has significantly declined, it does not mean that sand production has completely dropped off. In many cases, the well still produces sand — which can cause significant damage to your production facilities and downstream pipelines if it is not dealt with.

EnerCorp offers a number of desanding technologies and sand management services designed specifically for the steady state phase. Based on the unique characteristics of your well, we can reduce personnel requirements and HSE exposure by:

Offering a range of sand management solutions to address persistent solids production

Mitigating sand issues on your well after being hit by an offset nearby frac

Implementing remote monitoring and automation technologies to give real-time visibility of site conditions

Preparing reports for production related metrics

Supporting field logistics with your lease operators

Checking your facility on a daily or weekly basis

From flowback to early production to steady state, EnerCorp offers sand management services for the life of your well

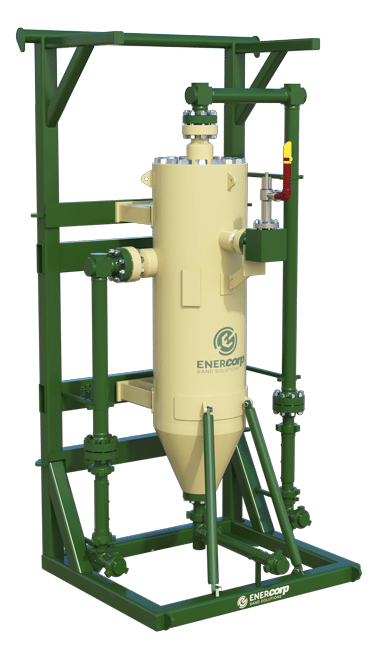

Sahara Facility Cyclone

A higher capacity and lower pressure unit for production facilities, with the same industry-leading technology as the Sahara Advanced Sand Cyclone

Smaller volumes of sand are still being produced during the steady state phase, and the Sahara Facility Cyclone is ideal for production facilities that are connected to multiple wells. Able to handle combined flow rates of 20, 30, 40, or more wells, this technology protects the facility from any carryover sand.

High sand capture rate: The Sahara Facility Cyclone can capture even smaller microns of sand as compared to the Sahara Advanced Sand Cyclone.

High sand capture rate: The Sahara Facility Cyclone can capture even smaller microns of sand as compared to the Sahara Advanced Sand Cyclone. Easy maintenance: There is no longer a need to maintain multiple sand management vessels at multiple wells. Consolidate it all into a single vessel.

Easy maintenance: There is no longer a need to maintain multiple sand management vessels at multiple wells. Consolidate it all into a single vessel. Minimal NPT: You can maximize production as your facility won’t need to shut down for repairs and cleanout since there is no erosion due to sand carryover.

Minimal NPT: You can maximize production as your facility won’t need to shut down for repairs and cleanout since there is no erosion due to sand carryover. Low operating costs: The Sahara Facility Cyclone is operator owned — which means no monthly operating costs.

Low operating costs: The Sahara Facility Cyclone is operator owned — which means no monthly operating costs.

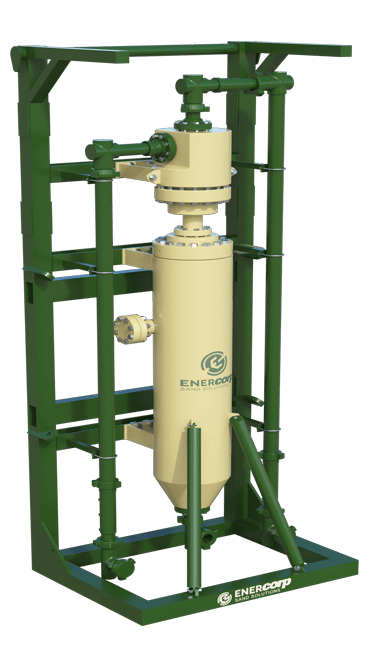

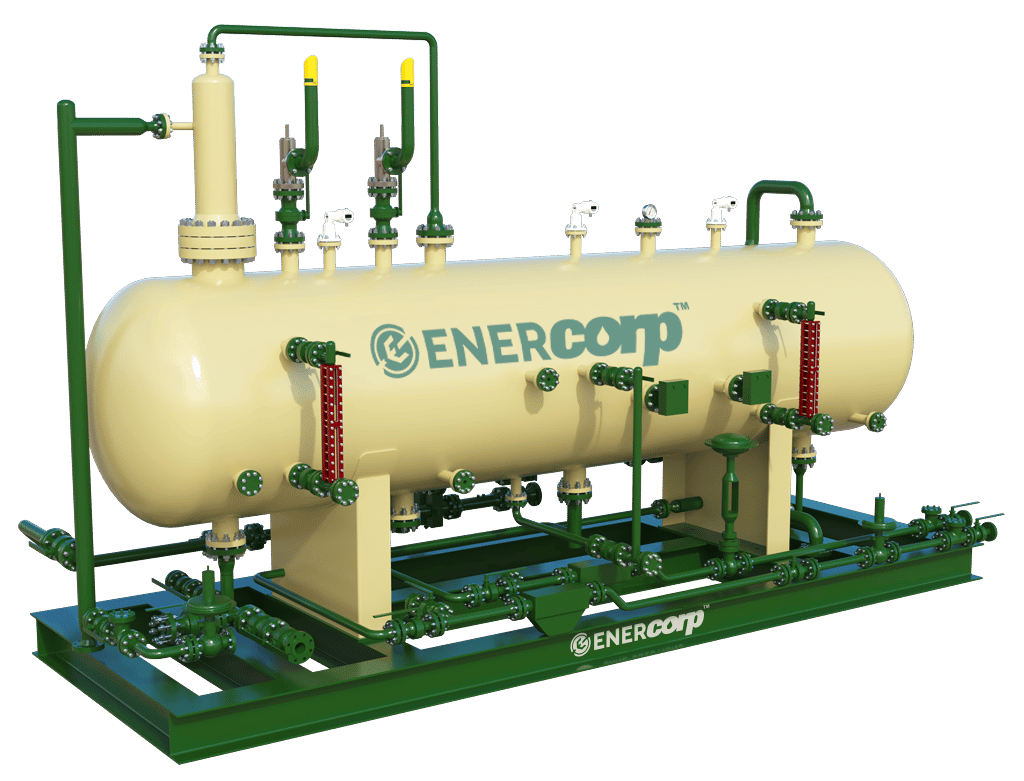

Four Phase Separator

Single footprint combines cyclonic sand removal technology with production stream separation

Extends capabilities of three phase separator to effectively remove sand in a single piece of capital equipment

World-class sand separation capture rate >97% with Sahara cyclone

Completely isolated chamber for sand separation – overflow from cyclone enters a three phase separation process

Water jetting system in the sand chamber allows for easy and complete evacuation of sand

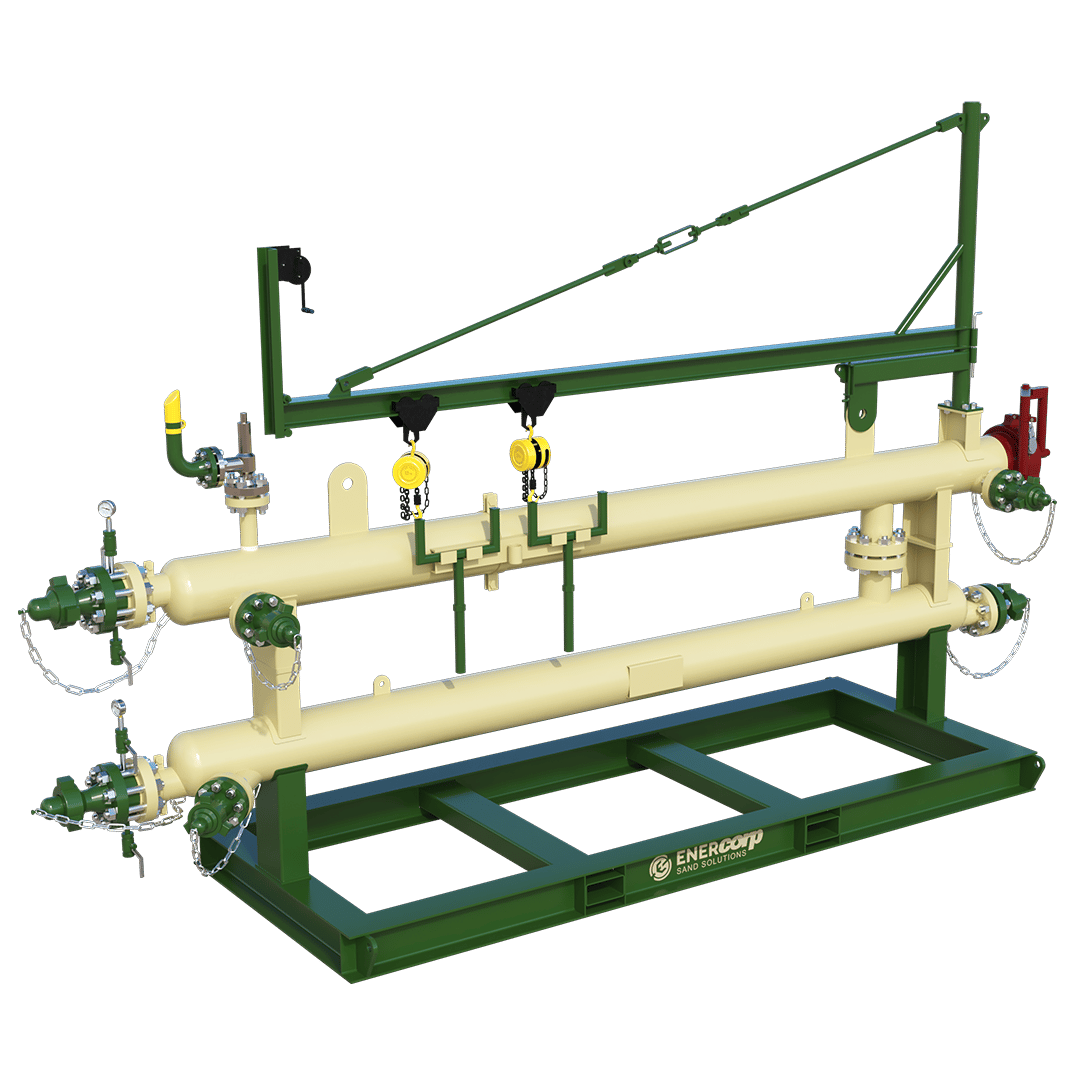

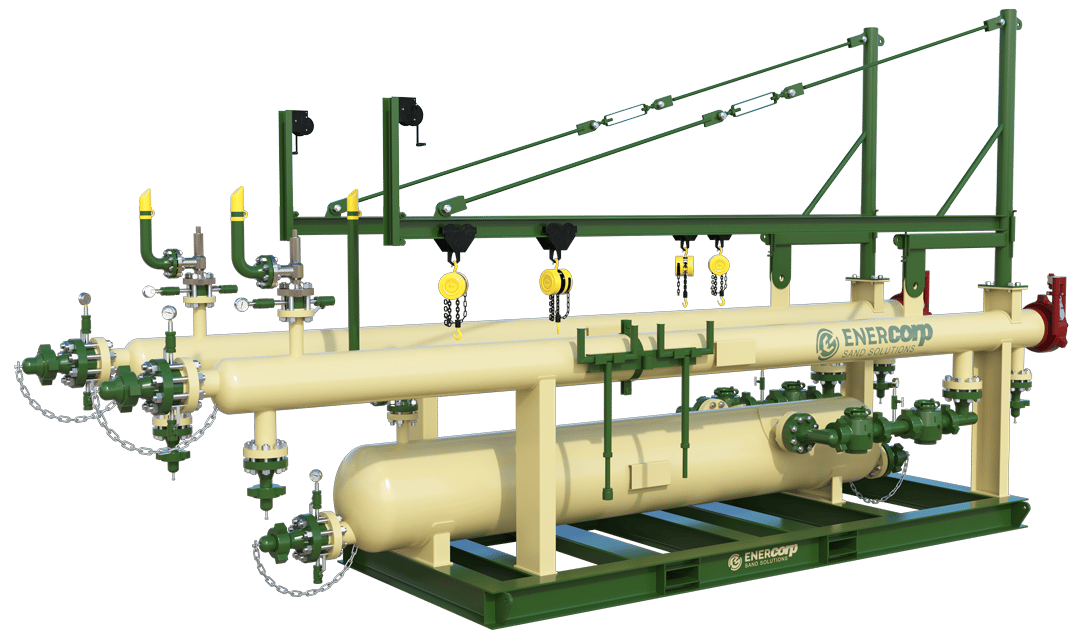

Multiple production skid configuration

World-class sand separation capture rate >97%

Highly accurate weight measurement connected to SCADA for operator call-out only when needed

Blowdown vessel fluid removal and recycling system eliminates extra trucking and disposal costs due to liquid

Blowdown vessel sand volume is monitored and connected to SCADA for disposal truck call-out only when needed

Self contained blowdown limits HSE exposure – potential for full closed loop system

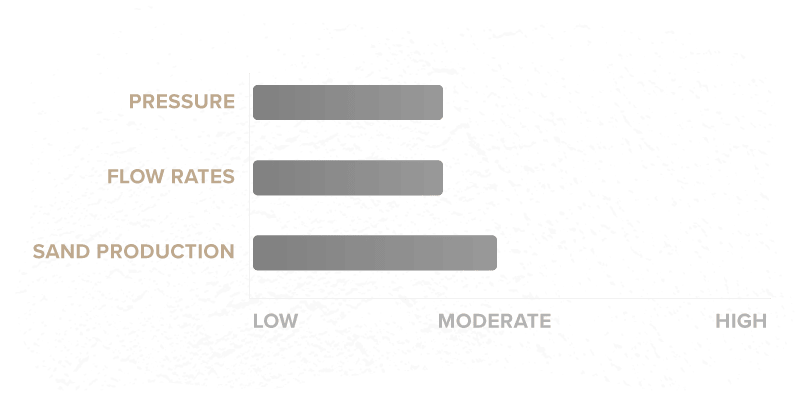

How can you minimize the risk of sand production during steady state?

Low pressure doesn’t always equal low sand production

Washed out belly dump valves and chokes or sand erosion on piping and pump components is still possible during steady state. When you’re not prepared with the right desanding skid configuration, this can have a major negative operational impact.

Do you want to avoid

Increased costs from replacing parts and cleaning out vessels or tanks

Constant non-productive time and lost production due to shutting in wells

Several environmental release incidents and clean up costs from washed out parts

High HSE exposure and emissions due to opening vessels or tanks

With industry-leading desanding technology and sand management services, EnerCorp can help.

The Sahara Cyclone Production Skid illustrated here is a singular example of a multitude of production skid configurations that can be provided.

World-class sand separation capture rate >97%

Highly accurate weight measurement connected to SCADA for operator call-out only when needed

Blowdown vessel fluid removal and recycling system eliminates extra trucking and disposal costs due to liquid

Blowdown vessel sand volume is monitored and connected to SCADA for disposal truck call-out only when needed

Self contained blowdown limits HSE exposure – potential for full closed loop system

Sand Separation Options

Cyclones

Filters

A combination of both cyclones & filters

Sand Cyclones

BOE per day

Sand Filters

Sand Capture Rate

Popular Production Skid Add-On Features

Digital Sensors & SCADA

- Pressure monitoring for filters

- Weight monitoring for cyclones

- Volume monitoring for blowdown vessels

Objective: deploy personnel only when needed

Blowdown Vessels

Fully contained vessel that can be tied in to onsite flare if needed

Objective: zero environmental or personnel exposure

Blowdown fluid recirculation system

Pump down the fluid in the blowdown vessel and reinject it back into the production stream

Objective: Significantly reduce the volume of vacuum trucks needed to dispose of sand and liquids waste from the blowdown vessel

Arctic Package

Winterize the unit to withstand harsh cold temperatures

Objective: eliminate downtime in winter