How often can you brag on your team about a perfect job?

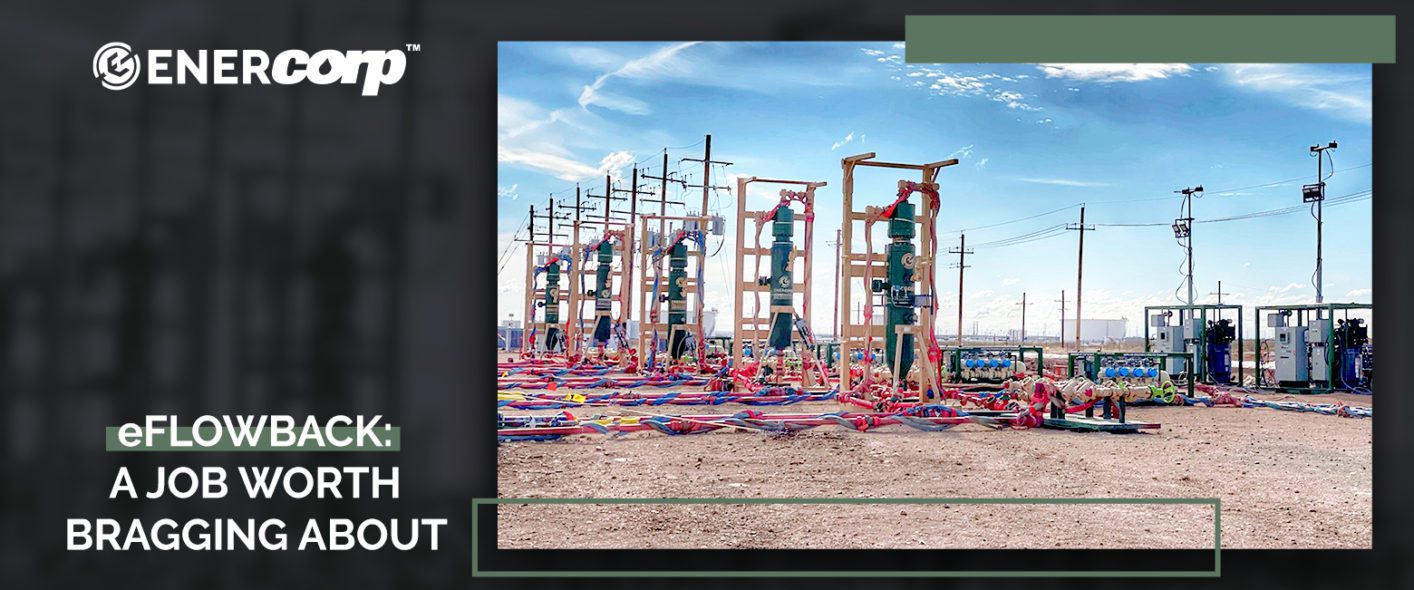

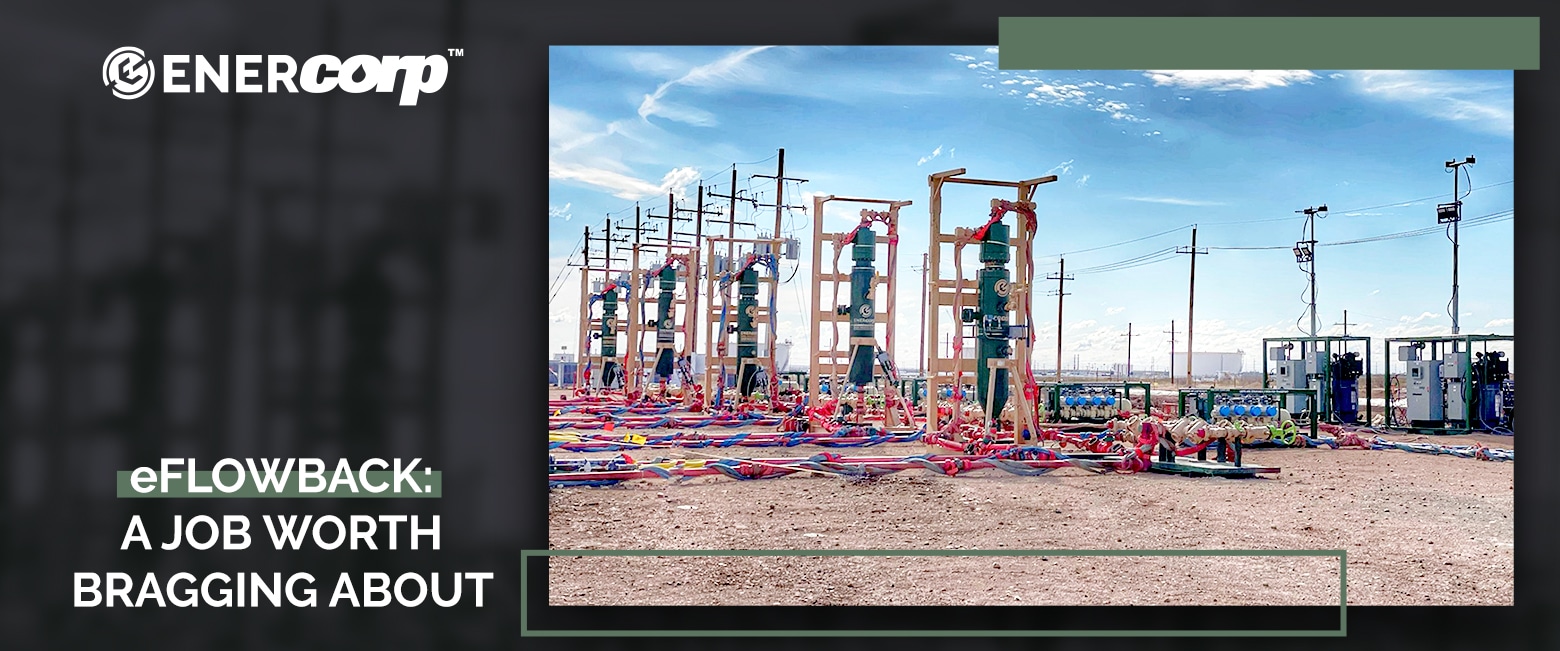

Our West Texas Flowback team was recently on a five-well eFlowback job that is brag worthy!

80% of the iron and equipment for the five wells was rigged up on the first day, and they finished running dump lines and restraints the second day. The team leak tested all five full packages the afternoon of the second day of rig up with zero leaks. That's a testament to our rig up crew and the way all the pieces are designed to fit in place like a puzzle!

The job was started on March 3rd with four flowback operators on days and four flowback operators on night. On March 7th, the team optimized crew to two flowback operators for day and 2 flowback operators for night. Then, on March 10th they were able to further labor efficiency by moving to a single day flowback operator and a single night flowback operator. It is truly remarkable to be able to optimize labor that fast on a five-well pad. On a traditional flowback, there would have been at least three day flowback operators and three night flowback operators for up to 45 days.

In addition to flawless execution and highly optimized labor, the eFlowback ecosystem managed about 275,000 pounds of sand, and ONLY about three cups of sand made it to the separator. These are truly remarkable results.

The eFlowback Ecosystem is changing the way you used to flowback, and the EnerCorp team is pioneering the way.

A special shoutout to Anthony Alaniz and Brandon Mayberry for knocking it out of the park on our eFlowback jobs.

Share this Post