EnerCorp Saves Client from Erosion Damages with Data-Driven Technology

The Problem

One of EnerCorp’s clients in the Permian region had their wells open and flowing for several weeks when we noticed a trend of extreme high velocity on the inlet of the Sahara Advanced Sand Cyclone.

The flow rates were significantly higher than expected, and if they were to continue, would result in major erosion damage. The high velocity had the potential to penetrate through the internal parts into the body of the Sahara Advanced Sand Cyclone used during flowback.

The Solution

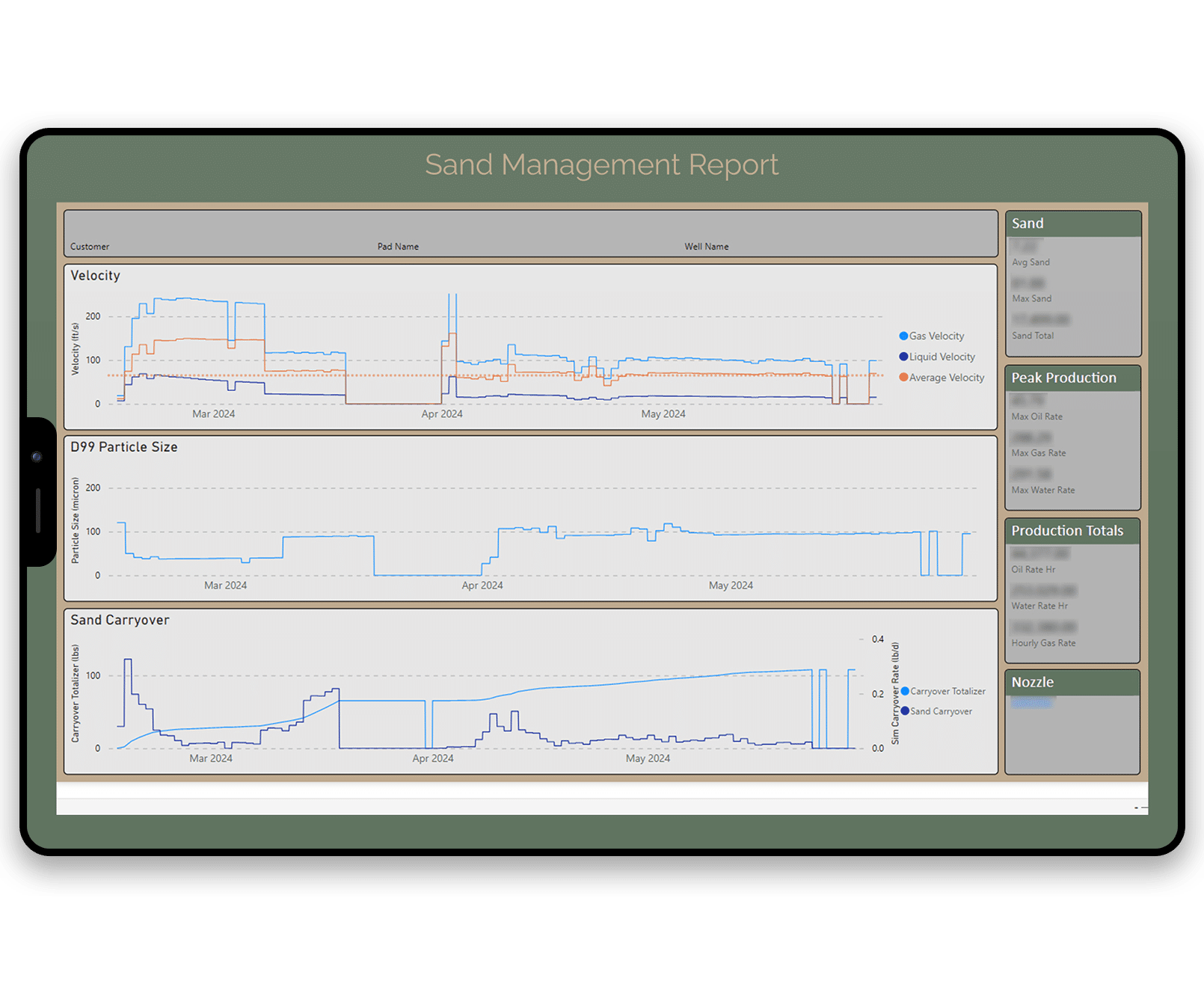

EnerCorp was able to notice the high velocities due to our proprietary Sahara Speedometer & Sand Management Report PowerBI Dashboard, which shows oil rate (bopd), water rate (bwpd), gas rate (mscfd) and average daily pressure (psi). The software simulates the performance of the Sahara, stores the data in a database, and has built-in alerts and notifications for high velocity and sand separation performance. It sends automatic notifications about high/low velocities to our engineers.

Without this proprietary reporting capability, there would be no way of accurately knowing that the client was operating out of specifications and could be damaging the equipment.

Our engineering team proposed a solution to the client to fix the high velocity issue:

Swap the Sahara Advanced Sand Cyclone unit: With velocities exceeding 100 feet per second for multiple weeks, it was highly probable that the internal components of the well had already begun to erode. Our engineers determined that swapping out the Sahara was necessary to ensure minimal disruption to the client’s operations.

EnerCorp was ready to make the switch on location within a day of the client approving our solution.

To do this, we coordinated with the operator a scheduled time to shut in the well, drained the vessel, bled off all trapped pressure, and removed the old Sahara. We swapped it with the new sand cyclone, pressure tested the equipment, and put everything back online.

In total, the wells were down for between 2-3 hours.

The Results

EnerCorp’s attention to detail on the flow velocities and quick turnaround time for getting the wells online saved this client a significant amount of operational expenses. Without our proprietary reporting capabilities which picked up on the high velocities, the client would have been dealing with major expenses from erosion damages.

Now, however, they can continue production without having to worry about high velocity issues — because they know EnerCorp will pick up on any issues and resolve them right away.

Want to work with a service provider that has your back? Get in touch with EnerCorp today.