EnerCorp’s ScorpionXT Sand Filter Eliminates Washouts and NPT, Increasing Production by $252,000 Per Month

Share this Post

THE PROBLEM

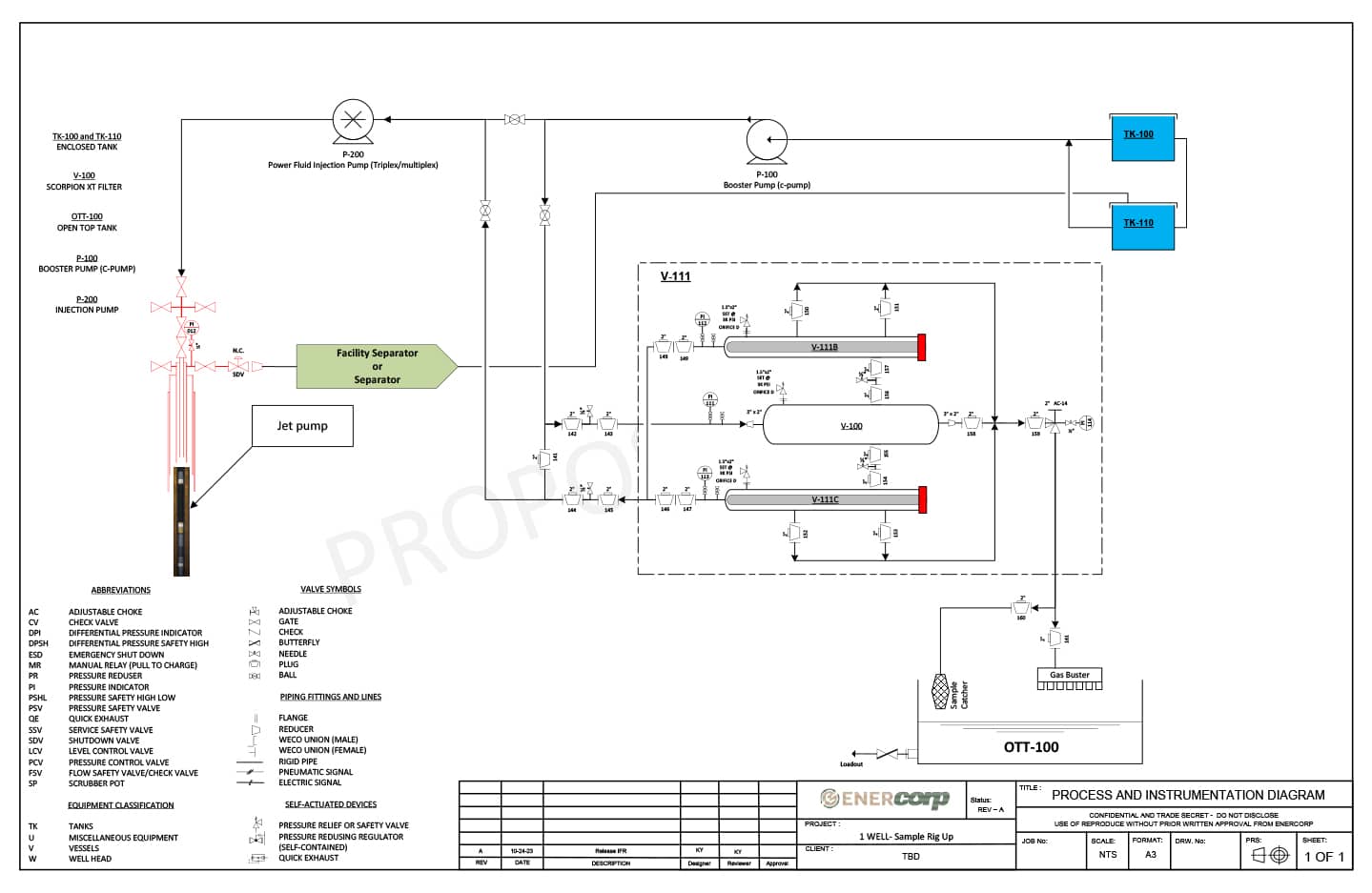

An operator in South Texas was dealing with lost production as a result of continuous sand damage to their jet pumps. These are multiplex pumps that have either steel or ceramic plungers that pump fluid under pressure into the well bore. The pumps fill the well bore and lift oil and water to the surface where it is separated in a multiphase separator.

The operator was only able to flow 3 days at a time before sustaining extreme damage to the jet pump plungers as a result of sand, causing shut down. It would take 2-3 days to get a mechanic out to make the needed repairs at a cost of $5,000 per visit.

This jet pump was on a 3-well set up, with each well averaging 70 BBLS of oil per day. This meant that every time the jet pump went down and the wells quit flowing, the operator was losing an average of 210 BBLS a day for almost a 3-day period.

The operator was only able to keep the jet pump flowing 15 days a month due to the needed repairs as a result of sand erosion damages. They needed a solution for the other 15 days of NPT each month.

THE SOLUTION

Our team of engineers reviewed the application and came up with a non-traditional solution that got the operator the results they needed.

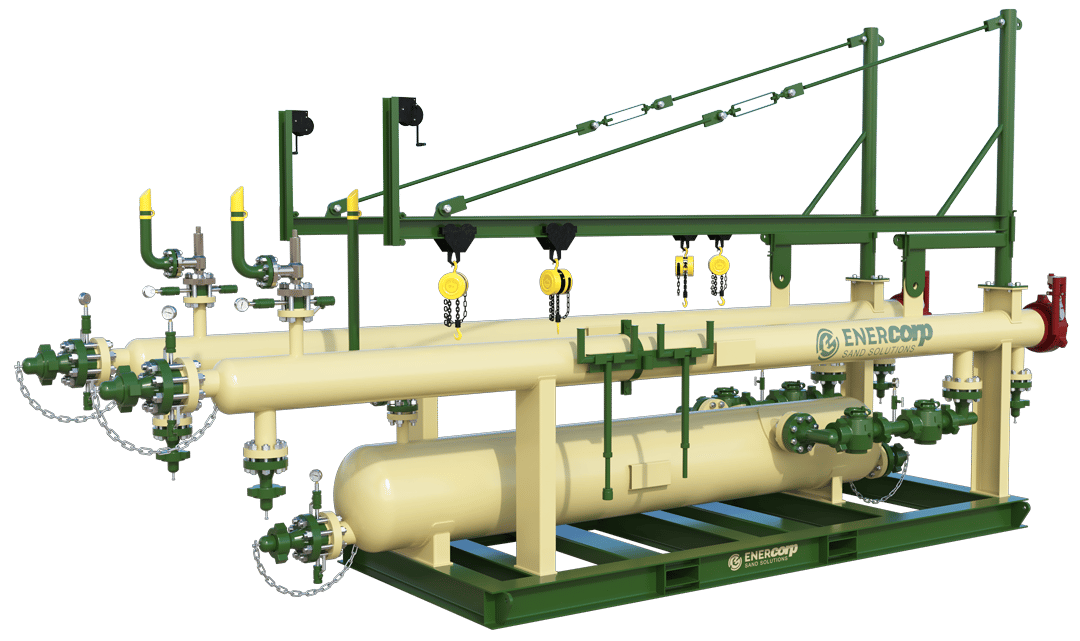

We suggested the operator use the ScorpionXT Sand Filter upstream of the jet pump system. The ScorpionXT Sand Filter, while designed for sand management during flowback, is the right choice for this application due to the high rates of sand carryover. It has a sand capture rate of over 99%, with a range of micron ratings for fixed media filtration.

SAND CAPTURE RATE

THE RESULT

EnerCorp drastically reduced the sand issues this South Texas operator was having by putting the ScorpionXT Sand Filter in line at the surface. Using a wire wedge wrapped screen, we are able to remove frac and formation sand down to 50 microns in size to eliminate erosional issues with the pumps.

The results were better than the operator expected. EnerCorp:

- Reduced non-productive time: Instead of only being able to run the jet pump for 3 days at a time, they can now run for up to 6 weeks at a time without issue

- Increased production: The operator can flow an additional 15 days per month, which increases their production by $252,000.

- Lowered operating costs: Instead of spending $5,000 on repairs five times per month, the operator can save $25,000 on a monthly basis.

The operator is no longer dealing with continuous sand damage to their jet pumps because the ScorpionXT is effectively mitigating the sand issue. They eliminated NPT, and are able to remain on schedule to reach their targets.

If you’re dealing with a sand-related issue — whether it’s a traditional flowback operation or at a well bore — EnerCorp has the right solution. Our engineering team brings the right application-specific equipment for the job at hand.

Get in touch with EnerCorp to learn more about the ScorpionXT Sand Filter and how it can get production back up and running.