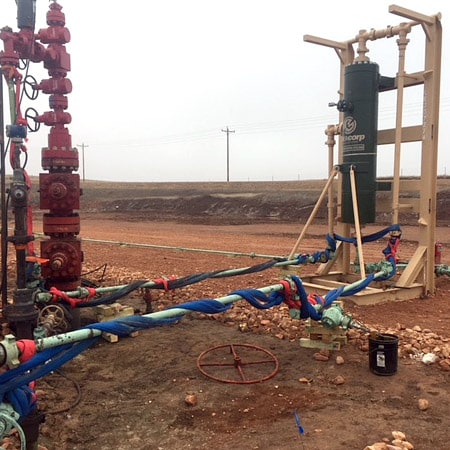

3000PSI DUAL CYCLONE. NORTH DAKOTA CASE STUDY

Share this Post

THE CHALLENGE

EnerCorp was called into a project, mid-week, with a report of a sanded-off wellhead. The client’s nearby well had a ‘zipper frac,’ and communicated with a preexisting well that had been on an artificial lift. EnerCorp arrived on location at 8:00am, bled off and rigged out the preexisting flowline.

When our team broke the production choke off, we found it completely packed off with sand. We then dug out the flange using a screwdriver in order to remedy the issue.

The well head had approximately 2400psi showing on the tree. We rigged in adjustable choke to an open top tank, which included a blowdown line from the base of the cyclone. We then pressure tested and opened the well to flow to the open top as wide as possible. This allowed the well to clear its throat, which lasted about 20 minutes.

The first few hours produced the bulk of the total sand return, around 40lbs. Our team opened and closed the adjustable choke, allowing the cyclone to recover just in time to blow it down again.

In addition, we also had one of our team members continuously sample down stream of the cyclone to ensure total sand removal. As the sand began to fall off, we increased the blowdown intervals, sending as much of the clean fluid to the production facility as possible.

THE SOLUTION

When the task was completed, the customer was incredibly happy with the performance of the EnerCorp crew due to our safe work practices, professionalism and knowledge to solve their sand problem.

From start to finish, EnerCorp received the call to rig up on a Wednesday at approximately 14:30 in the afternoon, then had it rigged up, flowing, and cleaned up by about 17:00hrs the following day.

“You really have your stuff together. A very professional company. I will be calling you guys again.” EnerCorp Customer Testimonial