Being a good neighbor: How EnerCorp uses our safety culture to improve safety posture for the oil and gas industry

Estimated reading time: 6 minutes

Table of contents

- The oil and gas industry has made great strides in the areas of health, safety, environment, and quality (HSEQ) over the last decade.

- The three pillars of HSE: Health, safety, and the environment

- Achieving Goal Zero — how we’re going to get there

- An HSE focus through flowback and sand management technology

- HSEQ is built into the EnerCorp approach

The oil and gas industry has made great strides in the areas of health, safety, environment, and quality (HSEQ) over the last decade.

Major players in the industry have prioritized the well-being of their employees as well as the well-being of the planet. Not only has HSE become more important to those within the industry, but it is also a focal point for partners, end consumers, investors, and other stakeholders.

At EnerCorp, HSE has been a priority at the company since its inception. Whether we’re on a wellsite in the Permian or the Haynesville, in the Northeast or Canada, everything from our processes to our technology to our operations is geared towards keeping our people and the environment safe.

The three pillars of HSE: Health, safety, and the environment

Focusing on HSE is all about being a good neighbor. When we say we make HSE a priority at our company, it is a commitment we make to every single stakeholder of EnerCorp as well as to the public around us. Some of our HSEQ policies have come about as a result of near misses while others are based on industry best practices. Our practical experiences combined with theoretical knowledge have led to a comprehensive set of programs we’re proud to share with the rest of the industry.

Health

Health and safety are often lumped together. While they are certainly connected, we see distinct differences. That’s why we have a Fit for Duty program and Fatigue Management program to ensure all of our employees are in good health on the job. We also conduct physical assessments and remote medical consultations when needed so our team can focus on their health and fitness and get the support they need to be at their best.

Safety

Many companies have a “safety first” motto. An EnerCorp, our motto is “safety always”. We don’t only think of safety as a priority, we think of it all the time. Safety is a core expectation and requirement of the business and is rooted in every part of our operations, from our engineering team to the personnel in the field. We establish safety protocols for every area of the business — and follow them closely.

Environment

There are many compliance regulations that oil and gas companies need to follow in the industry, but we see that as the bare minimum. Not only do all of EnerCorp’s operations meet regulatory requirements, we take things one step further to environmental stewardship. That’s why we engineer solutions like eFlowback and Flowback 2.0 to reduce environmental risks and exposure at the wellsite.

Achieving Goal Zero — how we’re going to get there

Our team at EnerCorp is always working towards the Goal Zero mindset. What does that mean?

- Zero injuries

- Zero negative environmental impact

- Zero equipment damage

With Goal Zero in mind, here’s what we have put in place:

- Why We Work Safe Campaign: EnerCorp makes safety personal to each team member. We want each and every person to be able to return home to their families at the end of each day without any injuries or illnesses. That’s why we constantly educate and train our employees on how to remain safe in the workplace.

- Push Don’t Pull Campaign: Many of our employees have very physical roles, where they need to lift heavy objects or work with heavy equipment. In order to remain safe and injury free, it’s vital to be aware of how our bodies work and the proper form we need to take during specific lifting, pushing, or pulling movements.

- 12 Life-Saving Rules: Our employees in the field are often in high-risk situations. In order to remain safe, we educate our team on 12 rules they always need to follow in order to prioritize the health and safety of the crew.

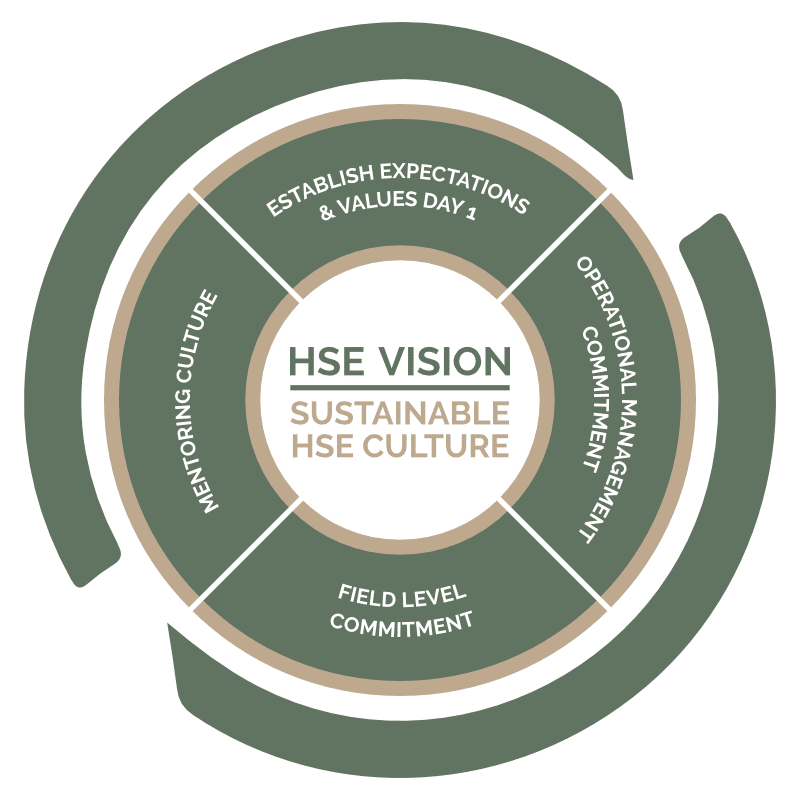

- Gold Hat and Behavioral Based Safety programs: These mentorship-style programs build relationships between leadership teams and employees, passing down knowledge to ensure HSE always remains a critical focus of the company.

- PQSSE: In order for employees to be qualified for safety roles in the company, we established actual competencies they need to pass. Only then do they get a white hard hat on the wellsite. We are not just checking boxes; we are ensuring employees are highly qualified and know their stuff when it comes to safety.

- Frontline leadership class: Our management and supervisory team gets a structured classroom course on EnerCorp’s safety culture, and learns the psychology of choices so they can better understand how to get employees engaged in making the right HSE decisions.

An HSE focus through flowback and sand management technology

While the processes and programs we have in place at EnerCorp certainly ensure our team is in good hands, HSE requires more than that. That’s why the technology we build has an HSE focus as well — it is designed to reduce health and safety issues for employees as well as minimize the risk of environmental exposures at the wellsite.

Our latest initiative, eFlowback, has completely transformed the way the oil and gas industry thinks about the flowback and sand management process. Traditional operations for flowback in oil and gas do not prioritize HSE goals. Hauling out a large amount of equipment to the wellsite, with all the personnel to operate it, is not only inefficient and environmentally reckless, but it also puts employees at higher levels of risk as well.

eFlowback, on the other hand, combines EnerCorp’s industry-leading sand cyclone technology with automation, measurement systems, and cloud-based software, so that operators can autonomously control flowback operations from a remote location. There are numerous layers of safety systems in place to prevent any environmental releases.

HSEQ is built into the EnerCorp approach

Not only is eFlowback designed to further EnerCorp’s HSE initiatives, but the core of our approach is built with HSEQ in mind.

Many service providers begin an engagement by sharing an equipment list with the operator. We don’t. At EnerCorp, we begin by understanding a customer’s requirements and desired outcomes so we can provide a tailored solution based on engineering recommendations. This ensures that we don’t haul unnecessary equipment out to the wellsite and release transportation emissions when we don’t need to. It also ensures that the best technology required for the application is used at the wellsite, so that there are less chances of environmental releases. Plus, this approach ensures employees are at their safest when they are using equipment that is tailored to the job at hand.

Our fit-for-purpose approach is used in every service we provide, from flowback and well testing to sand management services and beyond. Whether an operator needs desanding services or pre-set surface drilling solutions, they get a highly engineered solution that is in line with our company’s HSE values.

If HSE is a priority for your organization, let’s chat

Share this Article