Flowback and

Well Testing Services

We minimize the location footprint while exceeding your well flow management needs with state-of-the-art sand management technologies.

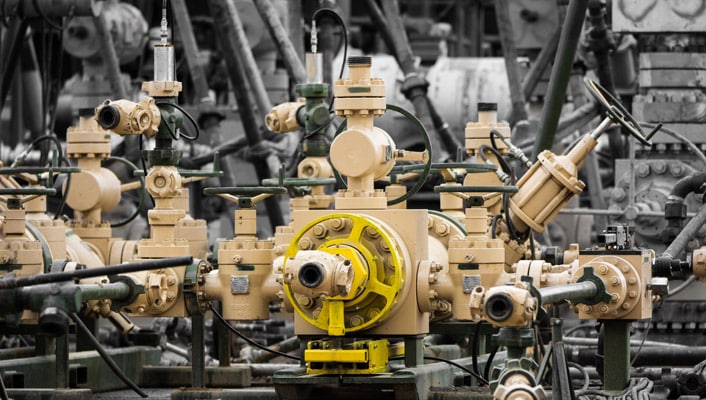

A highly engineered approach to flowback

Constructing a flowback layout doesn’t start with an equipment list.

We start by understanding the expected well flow regimes and anticipated challenges for the job. Our applications engineering team proposes the best solution to minimize equipment and personnel needs at your wellsite. To provide the best results, our solutions often include patented or proprietary technologies that eliminate any issues associated with sand and reduce emissions.

Imagine automating the entire flowback process while improving production results

Regardless of your needs,

we’re ready for the job

Some of our highlights include:

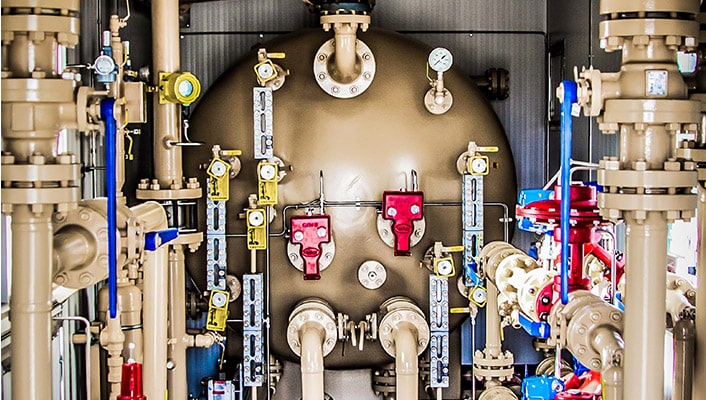

- Large fleet of four phase test separators in 42" to 60" diameters with the capability to handle up to 2,000 psi working pressure

- Hydraulic as well as manual valves, choke manifolds, and plug catchers in working pressures up to 15,000 psi

- NACE compliant vessels and piping to handle sour service operations

- Patented cyclonic and filtration technologies in working pressures up to 15,000 psi

See how we apply technology to deliver Flowback 2.0

Sahara Advanced Cyclone technology captures 99.7% of sand in the Permian Basin

Find out how EnerCorp’s Sahara replaced two sand separators and a three-phase separator with more effective results.

Sahara Advanced Cyclone significantly outperforms competitor “advanced” cyclone in the Marcellus Shale

Mojave Dual Cyclone reduces chargeback expenses by $25,587 on 15-day flowback job

Learn more about how EnerCorp can help you minimize post-job chargebacks from consumables and equipment damages.

Is your application different from traditional flowback? We have a solution for you

Whether your wells are in the steady state phase or you’re dealing with unusually low or high sand production at your wells, EnerCorp can help.

Introducing the latest innovation in sand management technology: The Sahara Facility Cyclone.

Designed to manage sand incoming from multiple wells, such as 20, 30, or 40 wells at a time, the Sahara Facility Cyclone can capture sand at a rate of over 97%, protecting the facility from erosion and damage.

Learn how you can increase sand capture, minimize the equipment footprint, lower operating costs, and increase HSE all in one go.

Would you like to learn more about the benefits of Flowback 2.0?

We enhance operations at each stage of your well’s life

We configure our technologies to support your well flow management requirements during toe prep, frac, drill out, and flowback. Additionally, we support clean out operations on your older wells.

Our operators have strong experience managing wellsite requirements from frac screen outs through drillout and flowback, continuing into all phases of production facility operations.

Have questions about our flowback solutions? Get in touch so we can learn more about your well’s requirements and offer the best technology solutions to ensure you meet your goals.