eFlowback automated sand management – What are you waiting for?

Estimated reading time: 5 minutes

The oil and gas industry has always been a tumultuous one, which means that operators need to constantly adapt and evolve if they want to come out on top. Innovation is the key to success in this industry, no matter which region you operate in. Both service providers and operators are constantly looking for ways to enhance production, reduce operating costs, and optimize labor costs.

At EnerCorp, we are ahead of the curve when it comes to evolution. Our autonomous flowback innovation, eFlowback, has been taking the industry by storm and propelling it into the future. Our eFlowback desanding technology combines industry-leading sand separation with innovative elements such as automation, measurement systems, and cloud-based software. This enables operators to autonomously control their flowback site with optimized equipment and personnel — helping them reach their goals. Whether operators are looking to reduce excess equipment on the jobsite to minimize safety incidents, reduce HSE exposure to the environment, or minimize sand flowing through to the production facility, they can do it with eFlowback.

If you’re sitting on the fence, considering whether you want to dive into this industry-leading technology for your operation, what are you waiting for?

Cost savings all around

EnerCorp operates in the Permian Basin / Midland, Odessa; Haynesville / East Texas; and Eagle Ford / South Texas, which gives our team an opportunity to experience different geographies with different sand management requirements. Because of this unique position, we are able to see that one-size fits-all equipment doesn’t enhance production — instead it can add extra costs.

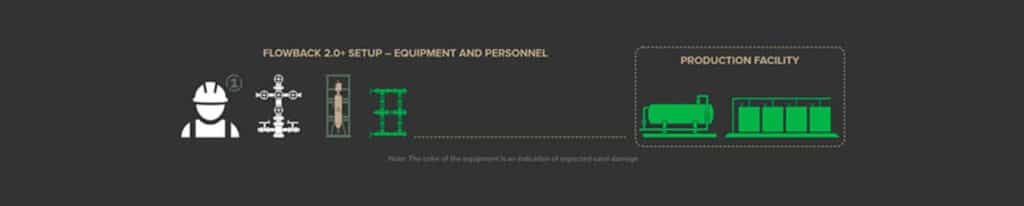

While this type of equipment is cheaper initially, it often leads to issues down the line, including costly damages to the production facility due to the poor sand management capabilities. eFlowback enables operators to create a customized setup based on their well flow rates and other requirements, ensuring that operators can meet their goals. This completely autonomous job site lowers labor costs and reduces the amount of equipment needed on site at all times, keeping a strict eye on your bottom line. Not only that, but damages to the production facility are eliminated, as with eFlowback the sand capture rate is in excess of 97%, often at 99%.

ESG benefits for a better future

While the cost savings are an excellent motivator for innovation, these days operators need more than just the promise of saving dollars. In addition to exceptional cost savings over the long run, eFlowback offers environmental benefits for the surrounding area and its people. For investors, employees, their families, and the community, this is an important aspect worth considering.

The eFlowback system was developed with ESG in mind. Take the Sahara Advanced Cyclone, a critical component in eFlowback, for example. This industry-leading sand separator delivers a sand capture rate of over 97% while reducing the equipment footprint on location. With less equipment on site, there are fewer transportation emissions released into the environment. Not only that, there is also less trash generated with eFlowback because there are fewer personnel on site.

With the Sahara Advanced Sand Cyclone, operators can bypass frac tanks and flow directly into the production facility. Because of this, there is less water and oil collection truck traffic, further reducing transportation emissions. The gas does not need to be flared because it is sand free. In addition, the storage tanks have vapor recovery units which recapture any emitted methane as the hydrocarbons flow directly to the production facility.

eFlowback in action

Reading about the benefits of eFlowback is different from actually seeing the technology in action and learning about the results it has provided other operators. eFlowback was developed in partnership with a leading Permian operator in the industry that wanted to reduce environmental exposure and increase safety for personnel on site, as well as optimize the workforce and reduce damages to the production facility. Previously, they had been using four Sahara Advanced Sand Cyclones and four daytime and nighttime personnel per well per day.

The EnerCorp engineering team, together with the operator, came up with the solution for eFlowback using a stringent research and development process that involved multiple risk assessments and hazardous operations studies. Over the course of a year of field testing, EnerCorp and the operator perfected the eFlowback solution, ensuring it was designed for a top-tier safety culture.

The results of putting eFlowback in place at the operator’s well are certainly eye-catching:

eFlowback enabled the Permian operator to save 26% on the day rate for a four-well pad, as compared to their costs using Flowback 2.0 (which already saves them 38% over traditional non-engineered solutions).

In addition to the cost savings, the operator now has complete transparency over the well site and everything that happens in it: every alert is logged and monitored by their personnel and any issues are addressed immediately. Personnel can find the root cause of any issues — even from a remote location. The operator can now also use the Sand Quantification Unit to accurately measure sand instead of using vague measurement categories as is so common with non-engineered solutions.

With eFlowback in place, this Permian operator is set to continue moving the industry forward when it comes to innovation. They not only helped develop eFlowback, but now use it on their wells to enhance production and meet their goals.

The time for eFlowback is now

There is no better time to take advantage of all that eFlowback has to offer. Optimizing labor, reducing costs, minimizing HSE exposure, and enhancing production — is there anything else you’re looking for?

Get in touch with EnerCorp today to learn more about eFlowback and what it can do for your operations.

Share this Article