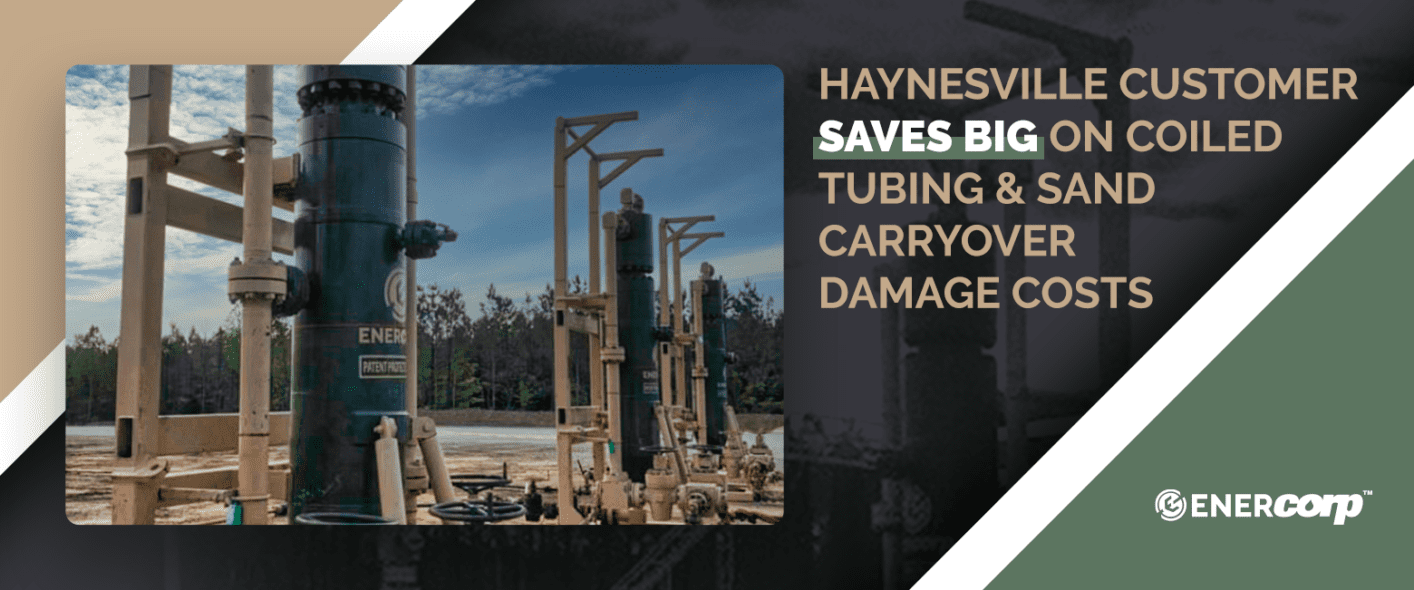

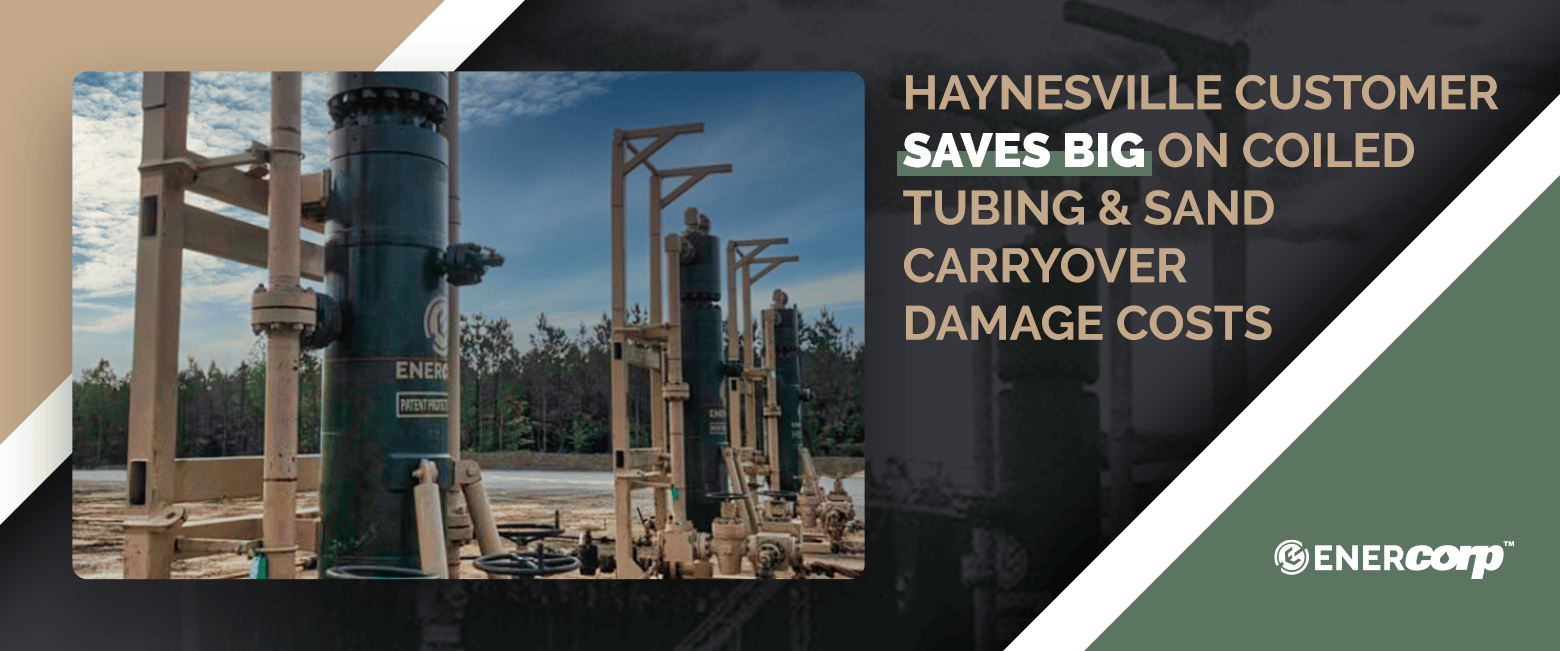

A client in the Haynesville was looking to reduce expenses while eliminating the need for coiled tubing to drill out plugs. This posed a major challenge for the customer because the lack of coiled tubing meant that more sand would be brought to the surface during flowback.

The EnerCorp engineering, operations, and sales team worked with the customer to design a custom solution. Over 28 days of flowback, the two wells produced a total of 35,328 lbs of sand. The Sahara Advanced Sand Cyclone prevented any sand carryover to the customer’s downstream equipment and prevented NPT.

In addition to saving on the cost of damages as a result of sand carryover, the customer also saved an estimated $200,000 per well on coiled tubing.

Read the full case study

Share this Post