How application engineering in flowback and sand management gets you better results

Estimated reading time: 5 minutes

Table of contents

When it comes to flowback and sand management, there are a lot of service providers out there ready and willing to do the job.

Many customers we work with have hired other companies before turning to EnerCorp — and we often hear about the same issues they experienced with the other guys: while the initial cost is low, other service providers only offer one-size-fits-all solutions that result in problems down the line. There is no technological innovation, and the service providers don’t have an application engineering focus.

At EnerCorp — the opposite is true, and that’s why many of our customers turn to us when they’ve had issues dealing with other service providers. In our industry, we’re an outlier: we don’t offer out-of-the-box solutions simply because we know from extensive experience that not every well works the same way. A well in the Permian isn’t going to have the same application characteristics as a well in South Texas or a well in Canada. As a result, the same sand management setup isn’t going to be as efficient as it could be. That’s why application engineering is so important — and why it ensures our customers receive the best results.

Why application engineering is important in flowback and sand management services

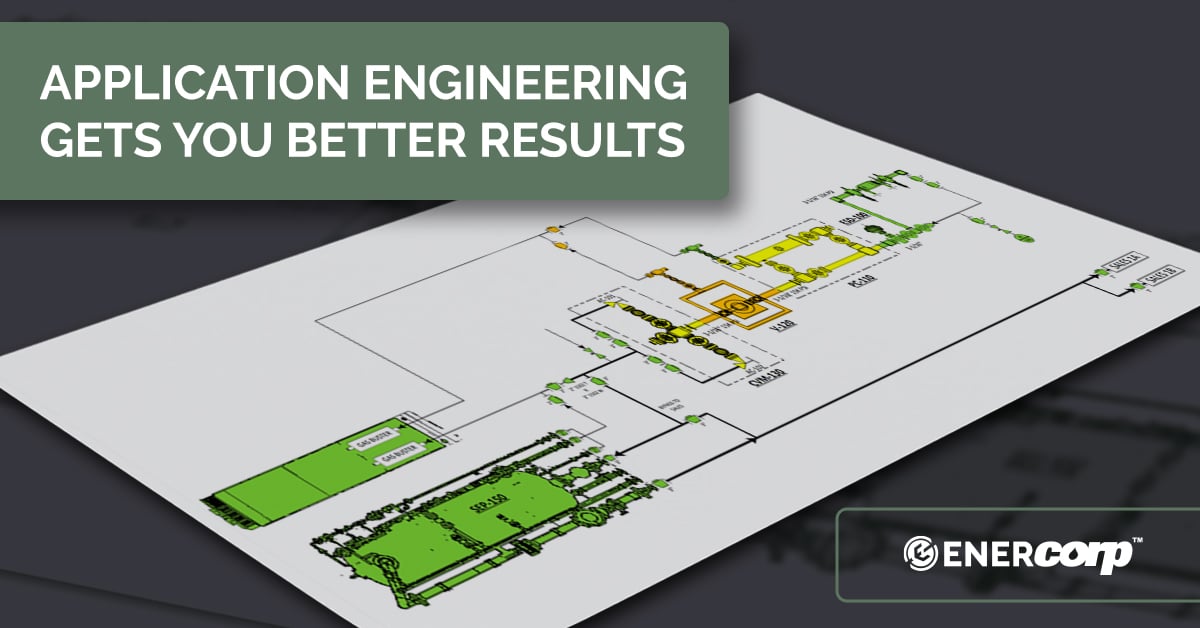

Our sales team brings application engineering into the conversation with customers early in the game — when we’re meeting with customers in their office. Our team discusses wellhead setup, flow rates, specific characteristics of the well, and what the customer wants to achieve. The Engineering team then delivers a custom flowback solution complete with a piping and instrumentation diagram (P&ID). This vertical integration gives EnerCorp a leg up as soon as we engage with the customer because our teams are tuned into the requirements of the job from the very beginning — not as an afterthought.

Custom fit solutions

In our industry, it’s common to begin a job by showing a customer a list of equipment a service provider has and the associated day rates, with the understanding that this out-of-the-box technology is all that is available to use. Not here. At EnerCorp, we see that every customer is different, with unique goals, procedures, and protocols. It’s simply not feasible to go by the industry standard if we want to ensure they get the best results.

Small changes we make to our sand separator or sand cyclone make a big difference on the flowback spread and how we operate it. While we have industry-leading sand cyclones like the Sahara or the Mojave, we know that they may not be a fit as-is for every customer.

EnerCorp Sand Cyclones

Our engineers make recommendations on the types of cyclonic sand separator the customer should use based on the flow rate they are expecting and the sand capture performance they require. We adjust the Sahara nozzle size for absolute peak performance as well as the flow iron sizing to ensure the layout is compressed to reduce the total amount of iron. This simply isn’t possible with one-size-fits-all equipment.

Clarity on the flowback job site

When a customer comes to us with a bid request, we quote exactly following the bid documents as well as our recommendation to help them achieve their goals. The P&ID is 100% transparent, so there is clarity between EnerCorp and the customer on what the engineered drawing is and what we will be bringing to the wellsite. This level of detail and open communication ensures that everyone from head office to the field on both sides is on the same page from the very beginning of the project.

This pre-planning stage is critical to our success because we plan for any possible problems that may occur. When both parties know what to expect, the project runs smoothly without any hurdles — and the customer gets to reach their goals without all the headache that comes when this amount of forethought isn’t in place. Time and time again, we hear from our customers how much they value the peace of mind they get when working with EnerCorp because they know things are going to work well and they are not going to deal with unexpected delays, costs, or issues.

Continuous innovation

The beauty of vertical integration is that we have the unique opportunity to improve our sand management services and flowback technology after seeing the results in the field. After the job is complete, we review what worked, what didn’t work, and what could use some improvement. Our application engineers are always looking for ways to increase the sand capture rate and reduce damages to achieve lower chargeback costs, for example.

We recently worked with a customer on differential pressure reduction to increase the yield of oil from the well. We split a single train flowback into a dual train flowback, and found that the pressure drop significantly increased oil production. This was a complete change from how this customer does flowback — and they wouldn’t have even considered it if our application engineers didn’t suggest it or have the opportunity to try it out. While this scenario works for this customer and their wells, it may not work for another customer — which is why having a custom solution for each customer is so important.

Our teams put gauges in different places to test specific applications. This is how we partner with the customer on innovation and see where we can make improvements that are specific to their well. Working in flowback in oil and gas every single day gives us a competitive advantage because we see how different wells react in certain scenarios, and we can use this knowledge to further innovate our processes and technology for our customers.

Application engineering is the differentiating factor for sand management success

From the Permian Basin to the Haynesville, Marcellus and Utica to Eagle Ford, different geographies create unique wellsites. With our application engineering expertise, EnerCorp goes on a journey with each and every customer. From the very beginning of the process, our teams help the stakeholders meet their objectives — whether that’s erosion control, differential pressure, higher sand production, or a different unique challenge.

After a consultation, our team builds a fit-for-purpose customer solution that meets our customer’s objectives and often exceeds their expectations. Our partnership with our customers is built on trust and expertise. It is clear to our customers that we care about their project as much as they do because we are always looking for ways to do it better.

Ready to see what a major difference application engineering can make to your flowback and sand management process? Get in touch with EnerCorp today.

Share this Article