Is sand production causing you issues late into your well’s life?

Estimated reading time: 6 minutes

Sand management is often associated with the flowback stage, but it is applicable to all stages of the well’s life, including the early production phase and the steady state phase. Using the right desanding equipment on the well — that is engineered to accommodate the different rates of sand production based on the well’s stage — ensures that the operator doesn’t end up with damages in the production facility or inflated chargeback costs.

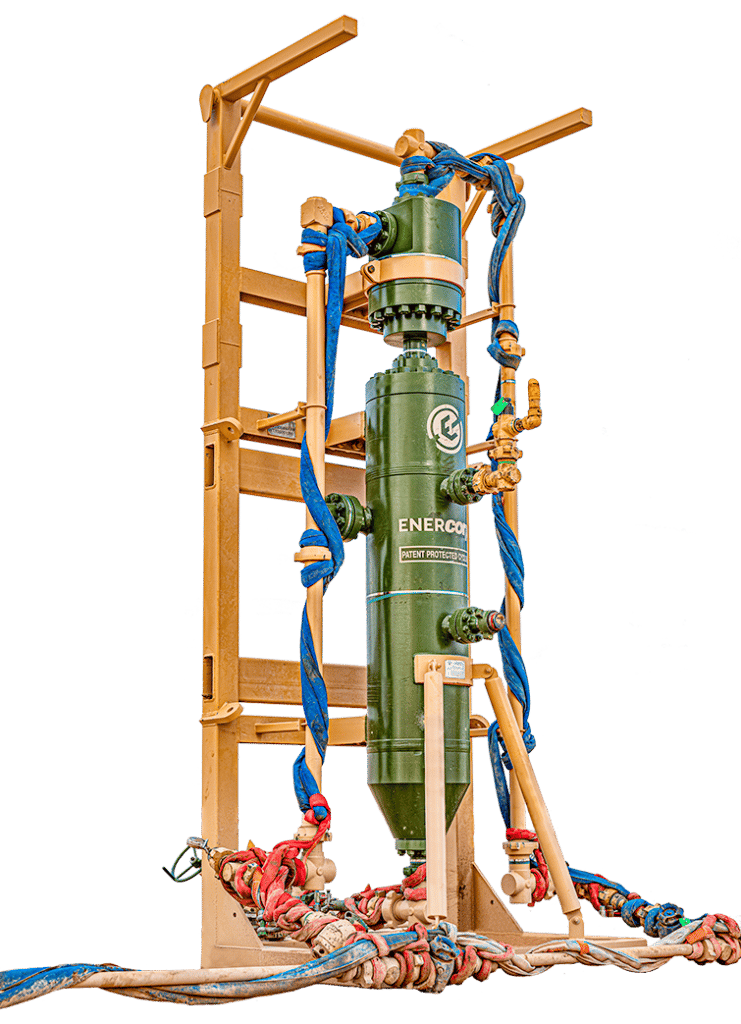

EnerCorp is a service provider that specializes in sand management equipment that is highly engineered to address a broad variety of sand separation challenges in the oil and gas industry — while reducing NPT, equipment costs, labor costs, and equipment footprints with a focus on enhancing production performance. If you’ve been experiencing sand production issues past flowback, read on.

Table of contents

Sand production across a well’s lifecycle

Persistent sand rates can vary from well to well and are dependent on a number of factors. It’s true that some wells produce sand in the initial flowback phase and then don’t produce any sand after that. In this case, operators typically only require the cyclonic sand separator during the flowback phase. However, other wells produce sand consistently for long durations, well into the steady state phase.

There are many contributing factors for how long a well produces sand, such as:

- Completion type

- Lateral length

- Frac and sand loading

- Formation properties

- Geographic location

In our vast experience working with operators and through our research, we have determined that the leading factor for sand production is geographic location. Some areas produce prolific amounts of formation sand and frac sand. Other locations hold frac sand and do not produce as much. Having extensive experience in the Permian Basin / Midland and Odessa, Haynesville / East Texas, and Eagle Ford / South Texas, we are ready to handle any application. We specialize in helping our customers push the boundaries of what is possible and achieve their production objectives.

Flowback phase

The rate of sand production is extremely high during flowback and this is the phase most commonly associated with sand management services. The fluid from the well contains a mixture of crude oil, natural gas, formation water, frac water, chemicals, and frac sand. Operators use sand cyclones to separate the sand and solid particles from the fluids in order to reduce damages to the production facility.

Early production phase

After the initial flowback phase, the well pressure begins to decline, but that doesn’t mean sand production stops. There is still a lot of potential for sand production during this stage, and it’s vital for operators to choose a fit-for-purpose solution that contains hydrocyclones, filtration technologies, or a combination of both.

Steady state phase

Most wells produce moderate to low levels of sand after the first year of life. However, a frac hit from a nearby well can be a major risk and can release sand into the hydrocarbon stream of the older well. Operators should use hydrocyclone and filtration technologies, in addition to four-phase separators, to effectively remove sand from capital equipment.

Highly engineered equipment for every phase of your well’s life

At EnerCorp, we don’t believe in one size fits all. While using the same sand management equipment on different wells with various well pressures and geographies is common in our industry, we know that fit-for-purpose equipment that is highly engineered for the job at hand produces better results.

Our Sahara Advanced Sand Cyclone is customized for each well based on a range of flow rates for oil, water and gas, wellhead pressures, sand particle sizes, and expected sand volumes. We recommend operators use the Sahara on longer-term production applications due to its large accumulator volume.

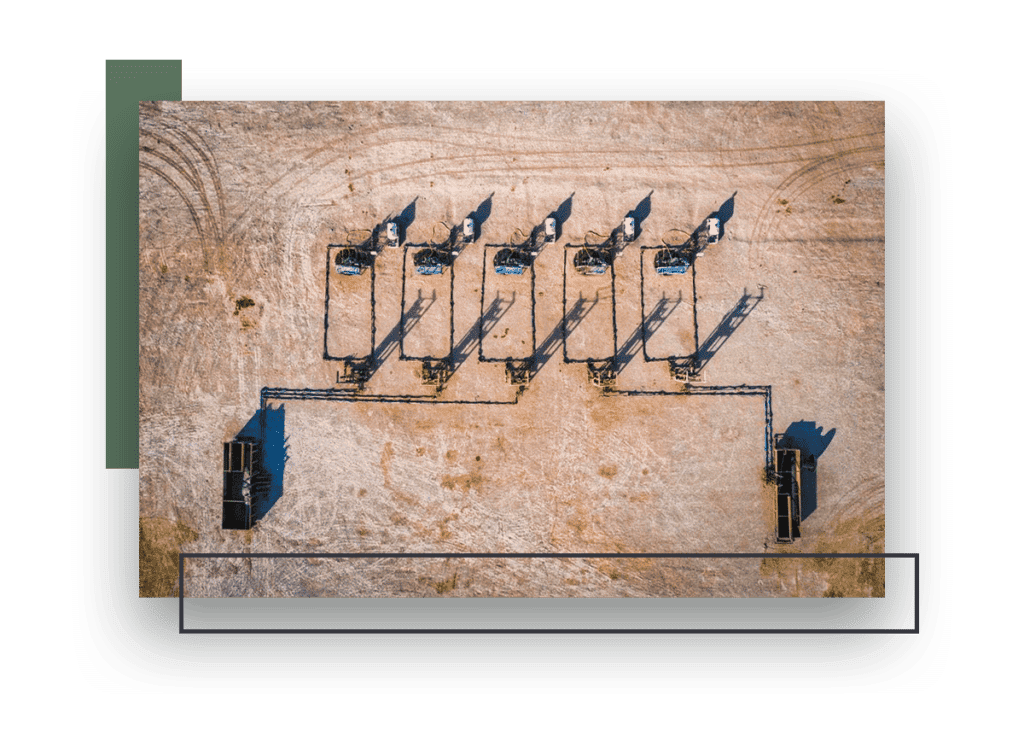

This enables us to leave equipment out on location and only have operators visit the site to blowdown the vessel periodically. A team of equipment operators have a “sand route,” much like a pumper route, that goes to different sites and monitors and maintains sand. This ensures operational efficiency while reducing costs for our customers — and providing a high level of protection for their facilities.

The proof is in the numbers

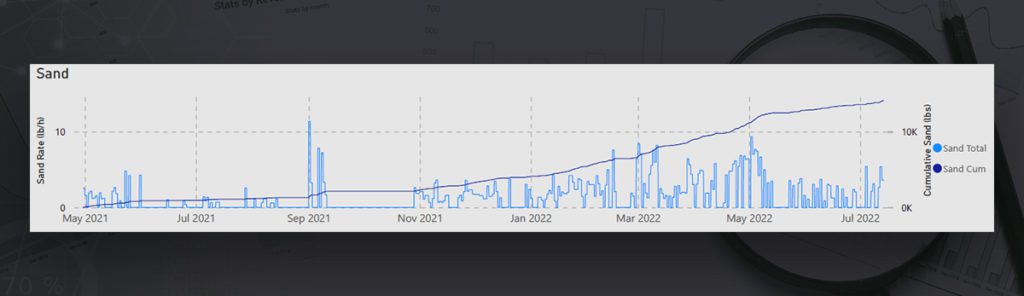

Let’s take a look at some real-life recent examples from the field. These are wells we’ve provided sand management services for across the whole lifecycle.

Well Jane was a significant strong producer in the flowback phase. An artificial lift was installed and sand production continued for a year and a half. Well Jane produced over 193,000 lbs of sand over the course of its life. 129,000 lbs of sand were captured during the first 90 days during the flowback phase. An additional 64,000 lbs were captured in the production phase.

Well Tom is our record longest sand producing well and we had sand management equipment out at the well for over 850 Days. It produced 7,617 lbs of sand in the first 90 day flowback phase, 16,548 lbs of sand in the first year, and then continued making another 11,473 lbs of sand over the rest of the 850-day sand management period. Slugs of over 250 lbs in a single day were common over this extended sand management job. Mojave Dual Cyclone and Sahara Advanced Sand Cyclone technology were used to keep these sand slugs out of production equipment for this extended run time.

EnerCorp supports sand management in flowback, early production, and steady states

With multiple production skid configurations that include industry-leading hydrocyclones, filtration systems, and test separators, EnerCorp is prepared for whatever levels of sand production come out of your well. Having extensive experience in the flowback phase and beyond, we can support your desanding needs at every stage of the well’s lifecycle.

From mitigating sand issues from nearby wells to implementing remote monitoring technologies to physically visiting your facility on a weekly basis, our team can handle it all. We also prepare frequent reports with production-related metrics so you can have a clear understanding of how much sand your well is producing in every phase.

Don’t let sand production during the later stages of your well’s life cost you. Get in touch with EnerCorp today.

Share this Article