Sand management for jet pump wells

Fit-for-Purpose Sand Management Equipment for Unique Applications

Estimated reading time: 7 minutes

Table of contents

Sand can be a persistent challenge in producing wells that utilize jet pumps for artificial lift. Particularly in areas like South Texas where there is low reservoir pressure and minimal gas production, sand in the production stream can lead to erosion, damages, frequent maintenance, and reduced efficiency of well equipment—as well as costly non-productive time.

The key to successful sand management for wells using jet pumps is all about selecting the right equipment for the right application. Instead of going for a one-size-fits-all solution or a status quo piece of equipment, operators need to choose fit-for-purpose sand management equipment that makes the difference between a high-performing well and one that leads to costly failures.

Bag filters, which are commonly used on jet pump wells, aren’t always right for the job. Sometimes you need to think outside the box and select a sand management solution that captures smaller particles and has a large accumulation capacity.

Why some jet pump wells need unique sand management solutions

In areas like South Texas where there are wells with low reservoir pressure and minimal gas production, sand management can be a tricky business.

Conventionally, operators go with bag filters to capture sand from jet pump wells. However, the problem with these filters is that they have a very small accumulator which needs to be changed constantly on wells producing a large amount of solids. Often, bag filters can only accumulate around 50 lbs of sand at a time. This means operators may have to change bags multiple times a day on some wells, increasing non-productive time.

For a sand management problem, operators need to consider more common sand management solutions, and cyclonic sand separators come to mind. However, these also don’t fit the bill for jet pump wells producing large amounts of sand. Cyclonic sand separators require fluid velocity or gas expansion to help separate solids from liquids. In low-pressure, low-gas wells, sand separators can’t generate enough force to effectively isolate sand from fluids, which results in poor separation efficiency. Sand and other solids then re-circulate through the jet pump, causing unnecessary damage to the equipment.

Another complicating factor for jet pump wells is that in many geographies, sand particle sizes are significantly smaller than what most traditional sand separators can handle. Imagine sand particles similar in size and consistency to baby powder. It easily passes through cyclonic sand separators, eroding pump components and clogging lines. Operators then have to shut down the well, repair the equipment, and lose thousands of dollars each day.

The good news is that bag filters and sand separators aren’t the only options available to operators. For operators interested in searching for non-traditional solutions to the sand management problem for jet pump wells, EnerCorp offers the Scorpion series of sand filters.

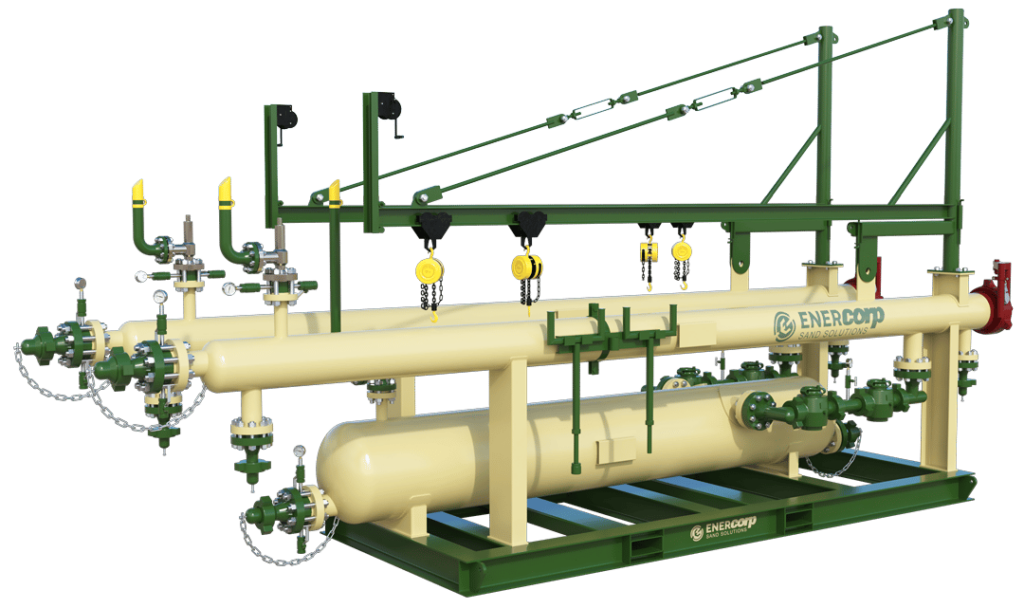

Meet the Scorpion series: Industry-leading sand filtration technology

At EnerCorp, we’re always looking for new ways to solve common problems operators experience.

Our Scorpion series of industry-leading sand filters, consisting of the ScorpionXT and the Scorpion, offer a higher sand capture rate than other sand filters on the market today, removing 99% of sand from the hydrocarbon stream. Plus, the Scorpion series of filters can accumulate 2,500 lbs of sand at a time, which is significantly more than bag filters.

ScorpionXT Sand Filter

Key specifications include:

- 3,000 psi pressure rating

- 200 degrees F max temperature

- 2,500 lbs daily sand removal

- 99%+ sand capture rate

- 7500 total bbls per day

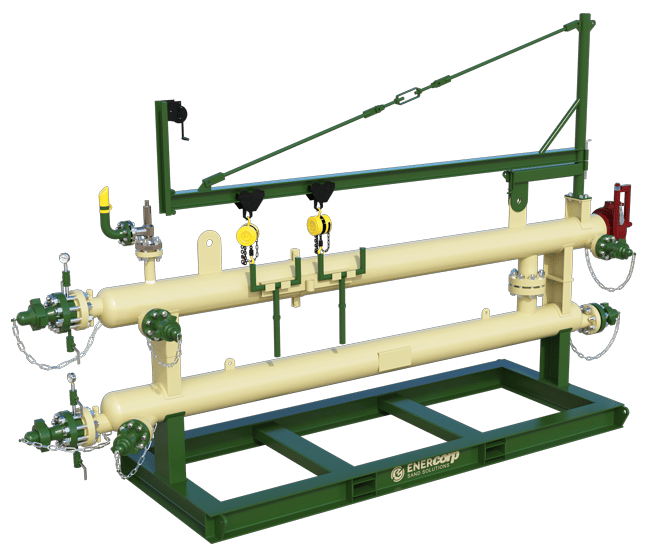

Scorpion Sand Filter

- 3,000 psi pressure rating

- 200 degrees F max temperature

- 1,000 lbs daily sand removal

- 99%+ sand capture rate

EnerCorp’s Scorpion series has been extensively tried and tested on thousands of wells in varying stages and geographies and with varying flow conditions, performing reliably each time. For unconventional wells and jet pump wells, especially those with low pressure, low gas, and high sand volumes, the Scorpion series offers impeccable results:

- Higher sand capture rates: The Scorpion series of filters use a range of screen wrap sizes from 100 microns to 300 microns, capturing more sand and iron sulphites than other sand management solutions.

- Smaller equipment footprint: Instead of using multiple bag filters or traditional sand separators that aren’t able to capture all the sand from the well, operators can minimize their equipment footprint with a single highly effective Scorpion sand filter.

- Lower operating costs: With less equipment on site, operators experience lower operating costs. Plus, the Scorpion minimizes damage to the jet pump and downstream equipment, reducing maintenance and repair costs.

- Reduced labor: Operators require fewer personnel on site as a result of a highly reliable sand management solution. There is less need for repairs and maintenance, and less reasons to shut down the well due to changing the bag in the filter or other sand-related issues.

See the Scorpion sand filter in action on a jet pump well

An operator in South Texas was experiencing sand damage to their jet pumps, resulting in lost production. The jet pumps are multiplex pumps with either steel or ceramic plungers which pump fluid under pressure into the well bore, filling the well bore and lifting oil and water to the surface to be separated in a multi-phase separator.

The problem

The problem with this equipment setup was that the operator was only able to flow three days at a time before seeing extensive damage to the jet pump plungers. Sand was not being caught by the multi-phase separator, which meant that the operator needed to pay around $5,000 in repairs every few days.

The jet pump was on a three-well set-up and each well was producing an average of 70 BBLS of oil per day. Every time the jet pump went down as a result of sand damage and the wells quit flowing, the operator was losing an average of 210 BBLS a day over a three-day period.

With the jet pump flowing only 15 days per month due to repairs and sand erosion, the operator needed a solution to reduce the 15 days of non-productive time each month.

The solution

EnerCorp’s team of engineers reviewed the characteristics of the well and determined that a non-traditional solution would be the best way to remove sand from the stream. We suggested using the Scorpion XT Sand Filter upstream of the jet pump.

Although the Scorpion series is typically used in flowback applications, it works exceptionally well on jet pump wells and other non-traditional wells. For this well in particular, the high rates of sand called for a solution outside of traditional sand management. With the wide range for micron screen sizes, we were able to dial in the correct size to capture the small particle sizes that only our Scorpion can capture, all while not restricting the wells performance.

The results

With the ScorpionXT upstream of the jet pump, EnerCorp was able to reduce the sand management issues this operator was experiencing considerably:

- 99% sand capture rate: EnerCorp removed frac and formation sand down to 75 microns in size, eliminating erosional issues with the jet pumps.

- Reduced non-productive time: Before the ScorpionXT filter, the operator could only run the jet pump three days at a time. Now, they can run it for up to six weeks at a time.

- Increased production: With an additional 15 days of flowing each month, production is up by $252,000.

- Lowered operating costs: The operator doesn’t have to spend $5,000 on repairs five times each month, and instead saves $25,000 monthly in operating costs.

EnerCorp can find the right sand management equipment for any application

No matter what type of sand management issues you’re dealing with, our team understands the importance of selecting the right equipment for the job. We think outside the box, developing unique solutions to every sand management problem.

Get in touch with EnerCorp today to learn more about our Scorpion sand filtration technology and see how we can enhance sand management at your jet pump well.

Share this Article