How can effective sand management and flowback 2.0 make a positive environmental impact?

Up until recently, the main measure of success for oil and gas companies was strong financial performance. However, stakeholders today also focus on ESG performance. Clients, employees, investors, and shareholders want to know what oil and gas companies are doing to lower the amount of emissions being released into the environment. They equate the importance of ESG performance with financial performance and operational efficiency — because they understand that an oil and gas company’s ESG performance will have a great effect on the future of the planet.

ESG at EnerCorp

At EnerCorp, we design our highly engineered solutions with ESG criteria in mind — not only because we understand its increasing relevance to today’s society, but also because we believe it is our responsibility to do so. As a result, when clients choose our flowback 2.0 solutions, they are in fact actively reducing emissions and making a positive environmental impact. Across the Permian, Eagle Ford, Marcellus, Montney, and Haynesville areas, our engineered solutions enhance client operations by improving both financial and ESG performance.

What is flowback 2.0?

Flowback 2.0 is designed to fully replace the traditional flowback process with a more cost-effective, highly efficient, and environmentally conscious solution. In flowback 2.0, we use our proprietary sand management services technology — the Sahara Advanced Cyclone or the Mojave Dual Cyclone — which has a sand capture rate of up to 99%, far exceeding any other options available in the market today.

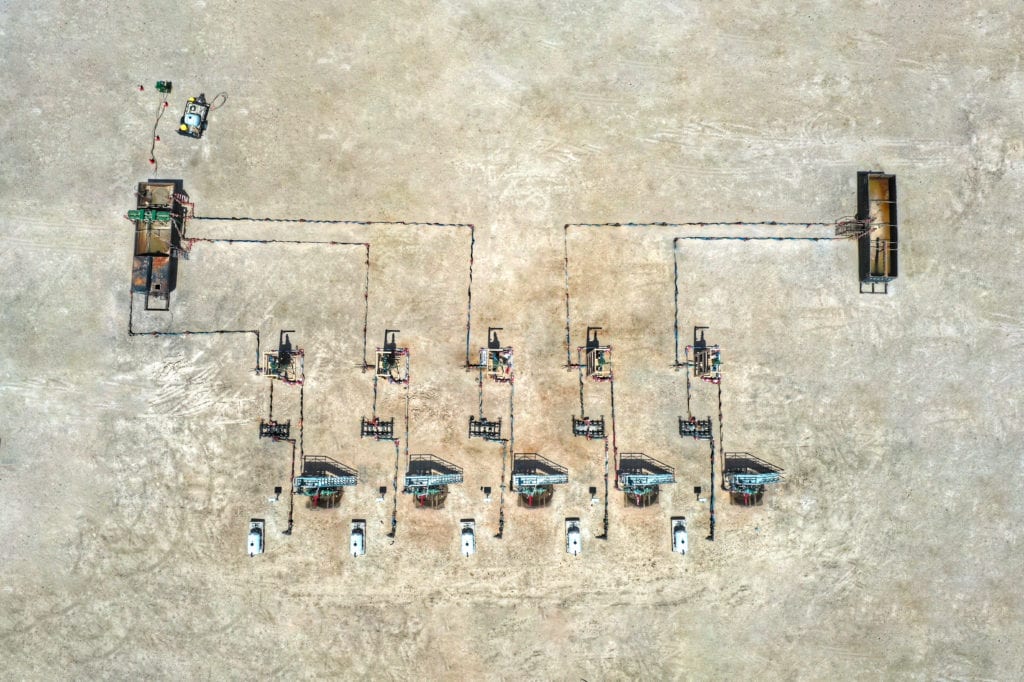

Because we capture virtually all sand, you can flow directly into the production facility without fear of any damage as a result of sand. This process minimizes the amount of equipment and personnel needed at the wellsite.

The key element that makes flowback 2.0 so effective is EnerCorp’s fit-for-purpose approach. We understand that the requirements of each wellsite are different, and as such, the technology solutions each site needs should be tailored. We look at the well’s expected flow rates and pressures, in addition to the expected sand production rates and tolerance for sand carryover. With this data in hand, we create the optimal sand management solution that results in flowback 2.0.

The environmental benefits of sand management and flowback 2.0

With less equipment and personnel on site, there are a number of ways flowback 2.0 makes a positive environmental impact not seen with traditional flowback services. Here are some of the environmental benefits our clients experience when using flowback 2.0 technology.

Minimal points of emissions

A key economic benefit of flowback 2.0 is that there is less desanding equipment at the wellsite. Typically, only one Sahara Advanced Cyclone is needed at each well. Compare this with non-engineered desanding services which typically require multiple units (and result in less sand capture).

When there is a smaller equipment footprint, there are less connections and less points of potential emissions. In addition, there is less truck traffic to get the equipment on location, which not only reduces truck emissions but also keeps roads safer.

Reduced transportation emissions

Using EnerCorp’s industry-leading cyclonic sand separator technology, clients can also reduce the number of personnel on site. This reduces the transportation truck traffic, resulting in less emissions. In addition, because there are less personnel on site, there is also less trash generated during their shifts.

No need to flare with flowback 2.0.

No need to flare

A massive benefit of flowback 2.0 is sand-free hydrocarbons that clients can flow directly to their production facilities instead of flowing to frac tanks. When flowing directly to production facilities, the gas can be separated off into the sales pipeline and does not need to be flared. This again reduces emissions on site.

Recaptured methane gas

Another huge benefit of being able to flow directly to the production facility instead of frac tanks is that this enables the operator to capture methane emissions from liquids. Production tanks in the facility are frequently fitted with vapor recovery units (VRUs) which are designed to recapture and pump gas that is emitted, while oil and water are in the tanks that go into the sales pipeline. If you are storing liquids in frac tanks, this gas is not recaptured and it goes into the environment. As you know, methane has four times the heating effect on the environment as compared to carbon dioxide, so it is imperative that we work towards reducing methane emissions. Also, when the methane is captured by the vapor recovery units, operators can sell it for an additional economic benefit.

No water or oil transport traffic

Since EnerCorp’s cyclonic sand separator technologies enable operators to flow directly from the well to their production facilities and bypass frac tanks, this means that the separated water and oil can go into pipelines as well. There is no truck traffic to collect the water for disposal or to take the oil to the terminal, as it all flows directly through pipelines.

A related economic benefit is that operators typically see a higher price for their oil which they sell directly through the pipelines as opposed to selling it via trucking.

Having trouble keeping your flowback costs in check?

Reduced costs, improved margins, and minimized emissions

With EnerCorp’s flowback and well testing experience, we have been able to develop industry-leading cyclonic separator technology that removes up to 99% of sand. This enables operators to flow directly into their production facilities without worrying about any possible damaging effects.

Across North America and beyond, our teams are revolutionizing the flowback process. By understanding your well’s expected flow rates and pressures, sand production rates, and tolerance for sand carryover, we can develop a fit-for-purpose hydrocyclone setup that enables you to reduce costs, raise margins, and minimize emissions.

The ESG performance of your oil and gas company is becoming as important as your financial performance. With EnerCorp’s flowback 2.0 sand cyclone technology, you can make a positive impact on the environment and your bottom line.

Want to take your environmental benefits up a notch?

When you fully automate flowback, you significantly reduce your environmental impact by lowering your equipment footprint and optimizing your workforce.

Share this Article