Why are you incurring the cost of utilizing temporary test separators during your flowback?

Estimated reading time: 5 minutes

The traditional use of test separators in flowback

Today, it’s common for operators to use test separators in the flowback space. Traditionally, these pieces of equipment have been required to provide test rate data during the initial production phase of a well’s life. Over time, test separators have developed into serving multiple purposes. For example, in some cases they handle excess water and fluid that is brought up during the flowback phase, in other cases they provide additional sand settling capacity to capture carryover from upstream sand separation equipment.

In this traditional flowback and sand management setup, there is a large equipment footprint, as well as high day rates. The risk for HSE exposure is also high, as is the number of personnel on the field. What if operators could optimize the desanding equipment during flowback and maximize their production without a temporary separator?

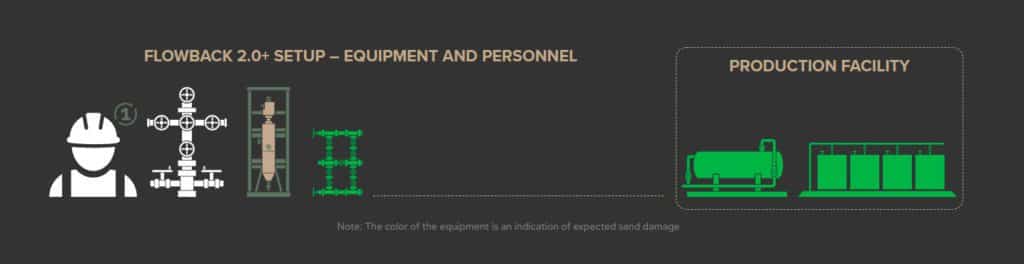

It’s not only entirely possible, it’s cost effective, environmentally friendly, and safe. At EnerCorp, we are constantly working to enhance and expand our sand management services to help our customers create more energy with less energy. With Enercorp Flowback 2.0+ we can completely eliminate test separators all together and produce to the production facilities from the very first barrel of oil.

Table of contents

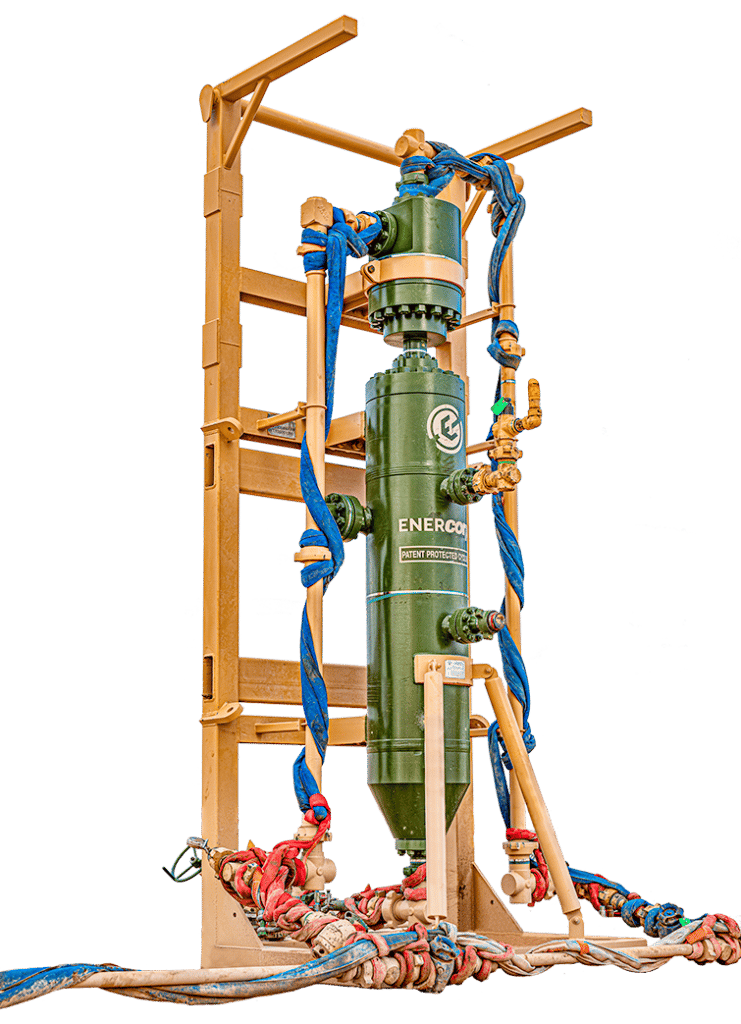

The Sahara Advanced Cyclone changes the face of flowback

One of the main reasons that operators don’t flow directly to their production facilities is because the sand particles within the stream can cause considerable damage to the facility. This results in additional costs during flowback, affecting the overall profitability of the well. With the right cyclonic sand separator technology, however, operators can capture virtually all solids from the production stream before it reaches the production facility, reducing the potential for any damages.

EnerCorp’s revolutionary hydrocyclone, the Sahara Advanced Sand Cyclone, is the leading cyclonic separator on the market today. Capturing over 97% of sand particles from the stream, the Sahara enables operators to flow directly to production from the very first moment of flowback.

No test separators, no flowing into frac tanks — just production straight to facility and sales.

The Sahara is so efficient at removing sand, there are no test separators required to provide additional sand settling capacity to protect production equipment.

The clear benefits of using the Sahara as part of your flowback setup:

Smaller equipment footprint:

Operators don’t need to haul out unnecessary equipment to the wellsite. With one Sahara Advanced Sand Cyclone, operators can experience more than 97% sand capture efficiency rate.

Lower operating costs:

When there is less equipment, there are lower operating costs. Operators can enhance their production efficiently.

Less HSE exposure:

Reduced equipment results in a smaller crew. This means operators can improve HSE risks from extraneous equipment.

Reduced labor costs:

Operators can optimize the workforce and only bring out the crew they need based on the smaller equipment footprint.

Minimized environmental impact:

With the Sahara, operators can reduce the potential points of emission by bypassing test separators and frac tanks and flowing directly to the production facility.

Here’s how we eliminate the need for a test separator

Operators can utilize production assets for the purpose they were designed for instead of relying on test separators to act as an additional sand settling vessel. The Sahara can handle the sand, and the production facility can handle the production. In fact, operators can optimize their usage of equipment by utilizing production assets from day one. There is no double paying for production separators AND test separators to perform the same task because the production separators are incredibly effective at their jobs.

It’s important to remember that production units typically have higher accuracy metering equipment as compared to typical flowback test separators. Test separators can act as another source of differential pressure holding back production from its full potential — affecting the efficacy and efficiency of the well.

During the flowback phase, EnerCorp’s engineering team works with the customer to specify the most efficient layout of equipment for the specific application. Enercorps industry-leading operations personnel can help to line out production equipment in the right way, ensuring that turning over to production is simpler and with fewer issues.

While other service providers use the same sand separators configured in the same way on different types of wells, at EnerCorp we understand that no two wells have the same characteristics. In order to help our customers achieve top flowback and sand management results, it’s vital to customize the sand cyclone based on operational and production design characteristics.

Our engineers configure the Sahara for each well based on these characteristics:

- Range of flow rates for oil, water, and gas

- Varying wellhead pressures

- Various solids and sand particle sizes

- Expected sand volumes

This fit-for-purpose approach is what leads the Sahara to capture over 97% of sand particles — more than any other sand cyclone on the market. No other sand management system can eliminate the need for test separators so effectively and offer clean production flowing directly to the facility without any risk for damages.

EnerCorp can meet every flowback need

EnerCorp is the leader in innovative flowback solutions. We want to work with our customers to provide the highest value solution for their needs.

In some cases, this can mean that they require test separators on a temporary basis to handle peak rates. Our engineers can design the optimal setup for flowback and sand management for the well and provide all of the equipment required to achieve the results our customers demand. For those customers who are thinking a step ahead, our teams can create a fully automated flowback site that can run autonomously and produce great results.

Throughout the Permian Basin, the Haynesvillle, and Eagle Ford, our goal is to optimize operations, minimize equipment footprint, and reduce operating costs for our customers.

Share this Article