How to enhance flowback while lowering your costs

Estimated reading time: 5 minutes

Enhancing production, lowering costs; These two goals are priorities for every operator. However, not all service providers prioritize these two goals for their customers, which can lead to long-term dissatisfaction. At EnerCorp, we understand how important it is for our customers to maximize their production while still keeping an eye on their bottom line. That’s why everything from our design to engineering to operations is focused around helping our customers reach their goals. From our sand management services and desanding technology to our innovative research and development, we know how to keep costs in check while maximizing the production of the well.

Table of contents

The future of flowback

EnerCorp operates in the Permian Basin / Midland, Odessa; Haynesville / East Texas; and Eagle Ford / South Texas, which gives us an opportunity to operate in different geographies with different sand management requirements. As a result, we have the ability to see that one-size-fits all equipment just doesn’t work. While it may be cheaper to start, sand management solutions that have not been customized for the specific wells needs do not enhance production.

At EnerCorp, we have innovated the flowback in oil and gas process by creating fit-for-purpose equipment. Our flowback services are available in multiple levels in order to meet the needs of the different geographies our customers operate in. Each level uses highly engineered sand cyclones that are tailored based on specific characteristics of the well. We minimize the equipment footprint as well as labor costs to keep an eye on your bottom line.

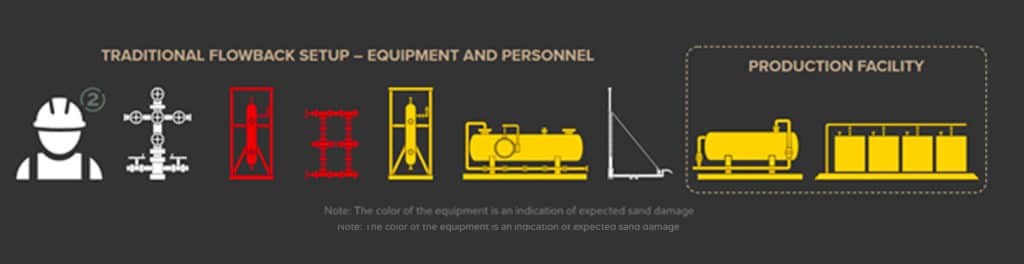

Flowback 1.0 or Traditional Flowback

If the well is producing a moderate to large amount of sand, there is usually a lot of equipment on location. This includes two sand traps, a plug valve manifold, a three-phase separate, and a flare. This set-up typically requires two well-site operators. Other service providers can offer you this traditional flowback setup, while EnerCorp goes a step further. Our desanding services can save on operating costs as we use highly engineered equipment that enhances production and reduces damage in the production facility.

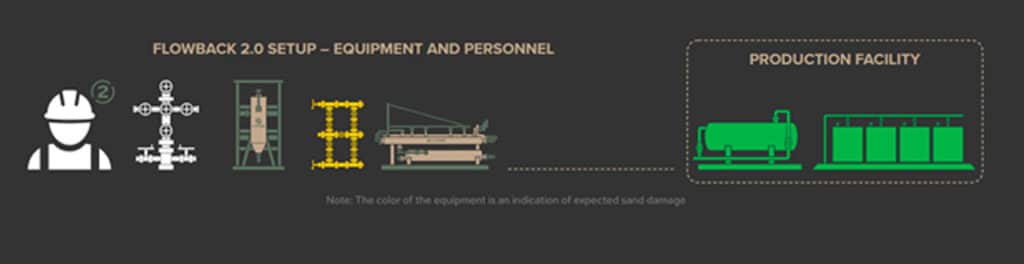

Flowback 2.0

EnerCorp is a pioneer in the evolution of this flowback process. Using the Mojave Dual Cyclone, which has a sand capture rate of 90%, we ensure the flowback process is highly efficient, especially with high flow rates. This two-phase cyclonic process has been tested and perfected on thousands of wellsites across the world, so the results will help you reach your production and cost goals. We also use our Scorpion and Scorpion XT sand filtration technology to bring the sand capture rate to 99% on certain well sites where required. This level of flowback works well in different geographies and is ideal for customers that want to move up from the traditional flowback setup.

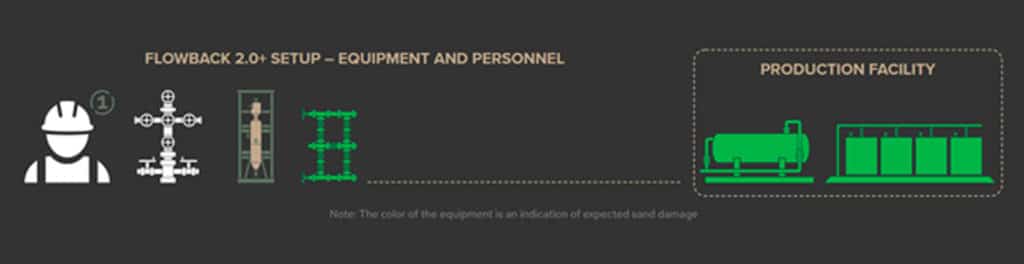

Flowback 2.0+

For enhanced results, this evolution of flowback uses the Sahara Advanced Sand Cyclone, a cyclonic sand separator that has unparalleled sand capture rates amidst a broad range of flow regimes. This sand cyclone removes over 97% of sand out of the hydrocarbon production stream, and is ideal for operators who want to minimize their equipment footprint while enhancing their production. With this set-up, there is also no need to pay double for production separators and test separators.

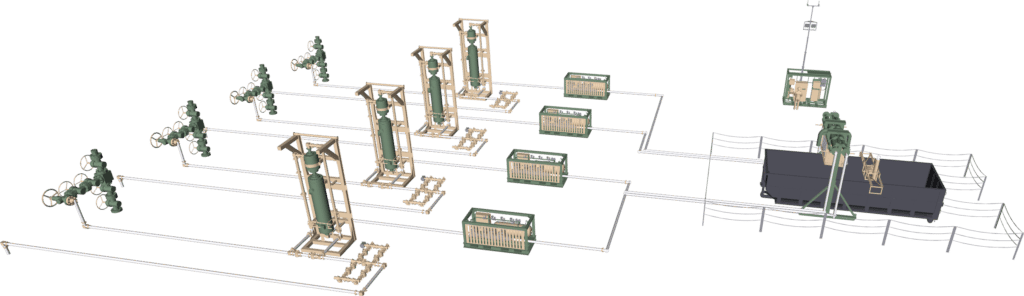

eFlowback

eFlowback combines industry-leading sand separation technology with automation technology, measurement systems, and cloud-based software, to create a fully autonomous job site. While it sounds like something from the future, it’s available and being used in the present day. This autonomous sand management solution is for those operators that want to reduce excess equipment, lower labor costs, and manage HSE exposure — while enhancing production at the well. With eFlowback, operators can control and monitor their well site from a remote location, from the very start of the flowback process.

EnerCorp is always focused on your bottom line

Our flowback sand management technology is designed to reduce long-term operating expenses by minimizing the equipment footprint and enhancing production through fit-for-purpose technology.

Check out these case studies to see how well our equipment works in the field for our customers — and learn about how much we have helped them save on operating costs.

Haynesville Customer Saves Big On Coiled Tubing and Sand Carryover Damage Costs with EnerCorp: We helped this customer save over $400,000 on coiled tubing while enhancing their production results.

Enercorp Enables Permian Operator To Save 26% On The Day Rate With Eflowback, Compared To Flowback 2.0: These savings were above and beyond what the customer saved compared to traditional flowback with Flowback 2.0.

Enercorp’s Sahara Advanced Cyclone Saves Operator In Haynesville Over $16,000 In Chargeback Costs For A Dual Well Flowback: With Flowback 2.0, this customer captured virtually all sand before it entered the production facility.

What’s worth more: enhanced production or lower operating costs

You can have both. Unlike with other service providers, you don’t need to choose at EnerCorp. Some service providers sell you one-size-fits-all equipment at rock-bottom prices, but then you may end up using multiple sand separators while still having sand go into the production facility. Others charge exorbitant prices for customized equipment that isn’t properly engineered based on well pressures and flow rates, resulting in poor performance.

At EnerCorp, you have the opportunity to reach both your overarching goals for production and expenses. That’s the bare minimum. Once you’ve reached your targets, you can still continue to enhance production and manage your operating expenses by exploring more of the industry-leading technology we offer.

Get in touch with us to learn more.

Share this Article