A Frac Valve Is Only New Once

What is the greatest benefit a frac valve provider can offer you during the hydraulic fracturing process? Peace of mind.

Our clients want to know that their operations are going to run smoothly and efficiently. They want to make sure there won’t be any delays or hiccups causing non-productive time (NPT).

We know that one of the worst things that can happen during hydraulic fracing is the frac valves malfunctioning. Because that means your entire operation comes to a halt — and you continue to incur expense — until the issue is rectified.

We help ensure you don’t have to worry about that.

What happens when you end up with a faulty frac valve?

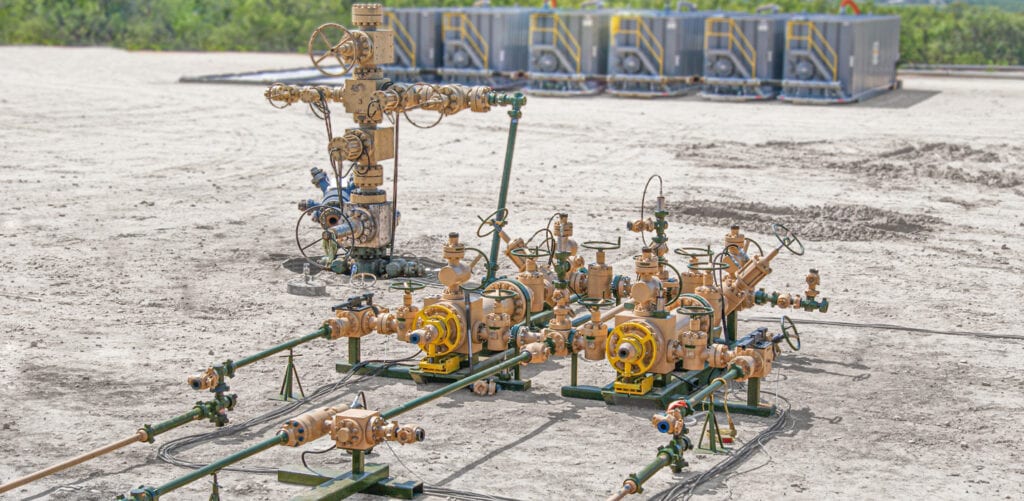

While it’s just one piece of the puzzle, frac valves (configured into frac stacks, frac trees, zipper manifolds, and monoline manifolds) have an important job to do.

Millions and millions of pounds of sand get pumped through frac valves at a high pressure. In the typical North American shale environment, the conditions frac valves have to endure are unnerving.

Millions and millions of pounds of sand get pumped through frac valves at a high pressure. In the typical North American shale environment, the conditions frac valves have to endure are unnerving.

If there is a leaky frac valve in your assemblies, the first thing that happens is your hydraulic fracturing operations come to a halt. You have to wait for the field crew to come and fix the leak — and until that’s complete you’re dealing with a lot of NPT.

Ultimately, this leaking frac valve causes costly delays on your wellsite.

Why do frac valves leak in the first place?

It’s important to remember that frac valves are only new from the manufacturing facility once. After that first use, they need a lot of maintenance and repair before they can be used again.

However, not all frac valve rental companies have a vigorous QA/QC process designed to ensure frac valves are working properly before they are sent to a customer’s wellsite. This is a major problem.

Why you should pay attention to the QA/QC process when considering frac valve rental

At EnerCorp, our approach to frac valves is different from the status quo. Offering our customers impeccable quality and maintenance is key — because we understand the ramifications of NPT.

That’s why we have an industry-leading quality assurance, quality control, and maintenance program for our frac valve rentals. Our program not only results in flawless execution of our frac valves at the wellsite, but it also provides our customers with peace of mind.

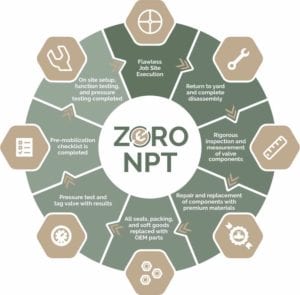

Here is an overview of our frac valve QA/QC process:

After each flawless job site execution, our frac valve is returned to our yard for complete disassembly. After the initial use of each frac valve, we increase the quality of care and maintenance.

After each flawless job site execution, our frac valve is returned to our yard for complete disassembly. After the initial use of each frac valve, we increase the quality of care and maintenance. We rigorously inspect each valve component: Once the frac valve has been taken apart, our technicians carefully inspect and measure each component to make sure that they stand up to manufacturer-specified tolerances.

We rigorously inspect each valve component: Once the frac valve has been taken apart, our technicians carefully inspect and measure each component to make sure that they stand up to manufacturer-specified tolerances. If anything is not working up to par, it’s time for repair or replacement. In case any frac valve components are damaged or worn out after use, they are carefully repaired or completely replaced. We do not cut any corners when it comes to our QA/QC process.

If anything is not working up to par, it’s time for repair or replacement. In case any frac valve components are damaged or worn out after use, they are carefully repaired or completely replaced. We do not cut any corners when it comes to our QA/QC process. Specific components are replaced with OEM parts: All seals, packing, and miscellaneous soft goods from the frac valve undergo complete replacement after every job. Regardless of their condition, we replace them with OEM parts.

Specific components are replaced with OEM parts: All seals, packing, and miscellaneous soft goods from the frac valve undergo complete replacement after every job. Regardless of their condition, we replace them with OEM parts. Next, it’s time for pressure testing. Once all parts have been inspected, repaired, and replaced as needed, we take the remanufactured valve assembly and pressure test it. Plus, we tag it with the test chart results so the performance is clear and transparent.

Next, it’s time for pressure testing. Once all parts have been inspected, repaired, and replaced as needed, we take the remanufactured valve assembly and pressure test it. Plus, we tag it with the test chart results so the performance is clear and transparent. We complete the pre-mobilization checklist. When it is time for the frac valve to head to another job site, our technicians complete a detailed pre-mobilization checklist. This ensures that we have inspected all necessary QA/QC components and that we are sending the proper configuration of frac equipment to the wellsite.

We complete the pre-mobilization checklist. When it is time for the frac valve to head to another job site, our technicians complete a detailed pre-mobilization checklist. This ensures that we have inspected all necessary QA/QC components and that we are sending the proper configuration of frac equipment to the wellsite. The frac valve is tested on the job site. At the well, we function test each frac valve in the stack from top to bottom. We conduct pressure testing as well based on our client’s procedures.

The frac valve is tested on the job site. At the well, we function test each frac valve in the stack from top to bottom. We conduct pressure testing as well based on our client’s procedures. The frac valves all perform flawlessly once again. Thanks to the intricate QA/QC process for our frac valves, they provide the kind of results our clients are looking for every time. Once the frac valve has done its job, it’s back to step 1 in our shop for complete disassembly.

The frac valves all perform flawlessly once again. Thanks to the intricate QA/QC process for our frac valves, they provide the kind of results our clients are looking for every time. Once the frac valve has done its job, it’s back to step 1 in our shop for complete disassembly.

When looking at frac valve rental companies and frac equipment rental, don’t settle for anything less than perfect.

If you want to eliminate NPT as a result of frac valve leaks, then choose a frac valve company like EnerCorp that has an industry-leading QA/QC process.

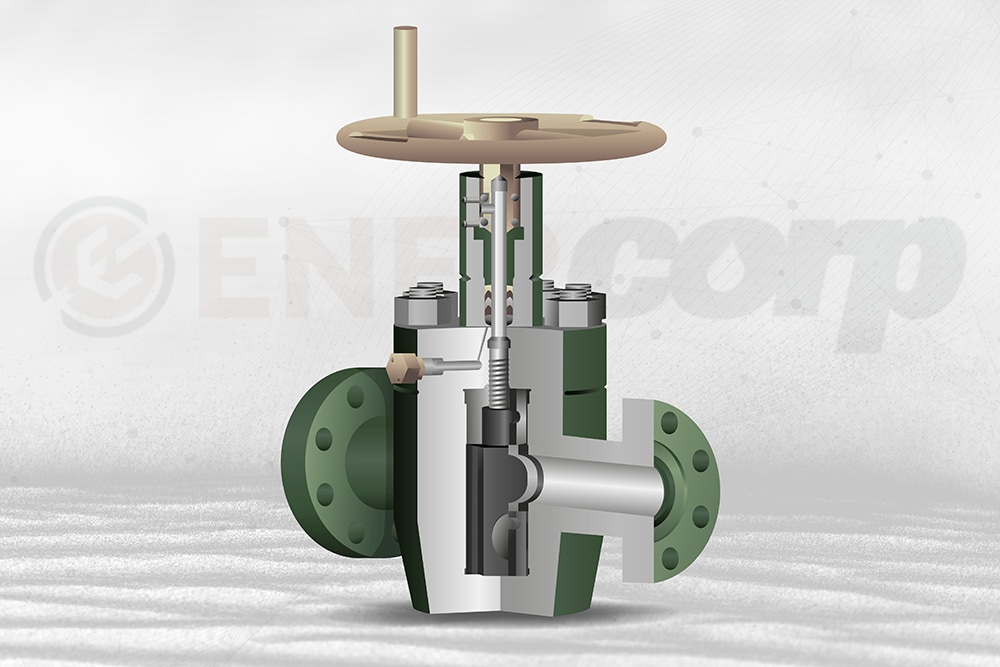

Our frac valves can withstand the pressure of your wellsite

If a frac valve is only new once, but they are used multiple times on multiple job sites, how can you guarantee the quality you need? It’s important to be aware of the specifics so you don’t end up facing challenges like leaking frac valves, halted hydraulic fracturing operations, and excessive non-productive time.

Here’s what you can expect with EnerCorp’s frac valves:

High-quality manufacturing of all parts in North America

High-quality manufacturing of all parts in North America Premium erosion-resistant materials

Premium erosion-resistant materials Performanced-focused QA/QC processes

Performanced-focused QA/QC processes Rigorous inspection and rebuild procedures after each job site

Rigorous inspection and rebuild procedures after each job site Both 5-1/8” and 7-1/16” frac valve sizes available as manual and hydraulic actuated

Both 5-1/8” and 7-1/16” frac valve sizes available as manual and hydraulic actuated Capable of supporting requirements up to 15,000 psi working pressure

Capable of supporting requirements up to 15,000 psi working pressure Can configure zipper manifolds and monoline setups to support your stimulation needs

Can configure zipper manifolds and monoline setups to support your stimulation needs Support for toe prep, hydraulic fracturing, drillout, and flowback operations

Support for toe prep, hydraulic fracturing, drillout, and flowback operations

EnerCorp is one of the leading frac valve rental companies in Texas, Louisiana, and around the world

If a frac valve does its job, you may not notice it or even think about it. But if a frac valve is faulty — you’re going to know right away. We understand that on the job site during hydraulic fracturing operations, there is a lot going on and a lot you need to oversee. Our performance-tested and carefully inspected frac valves do their job so seamlessly you won’t even have to think about then.

If peace of mind is your goal, choose a frac valve rental company that understands the importance of having a rigorous QA/QC process. We know a frac valve is only new once — which means that after the initial use, it needs a lot of maintenance and care.

Get in touch with EnerCorp today to learn more about our frac valves. Our team of highly trained engineers, technicians, and field crew are ready to eliminate NPT from your hydraulic fracturing operations.

Share this Article