EnerCorp is ahead of the curve when it comes to ESG – In Canada and the United States

ESG in the oil and gas industry is an ever-evolving area. Not only is it being regulated in many parts of the hydrocarbon recovery process, but it is something that is on the minds of investors, the media, partners, and vendors. The “E” in ESG, environmental, is arguably what stands out in the minds of people when they consider ESG as a whole, and rightfully so. While the oil and gas industry hasn’t traditionally had an urgency behind the development of emissions and spill reduction technologies, things are changing rapidly. Today, many oil and gas companies are focusing on how they can create more energy using less energy, and EnerCorp is leading the charge in our segment of the industry.

Estimated reading time: 6 minutes

EnerCorp technology is prevalent in many areas of the world, including the United States, Canada, and more. While the United States has certain ESG regulations that we follow, other countries, such as Canada, have stringent environmental regulations that must be abided by. Operating in Canada since 2006, we have been following ESG regulations for sand management, and have seen the cultural influence migrate south to the EnerCorp operations in the United States.

Table of contents

EnerCorp’s Canadian operations profile

Our Canadian operations primarily focus on production equipment for Early Production and Steady State phases of the well life cycle. Wells in Canada tend to produce sand prolifically from the start of production and far into the well’s lifecycle. As a solution, we rent and sell a variety of technology to help operators with sand management for improved production throughout the entire lifecycle of the well.

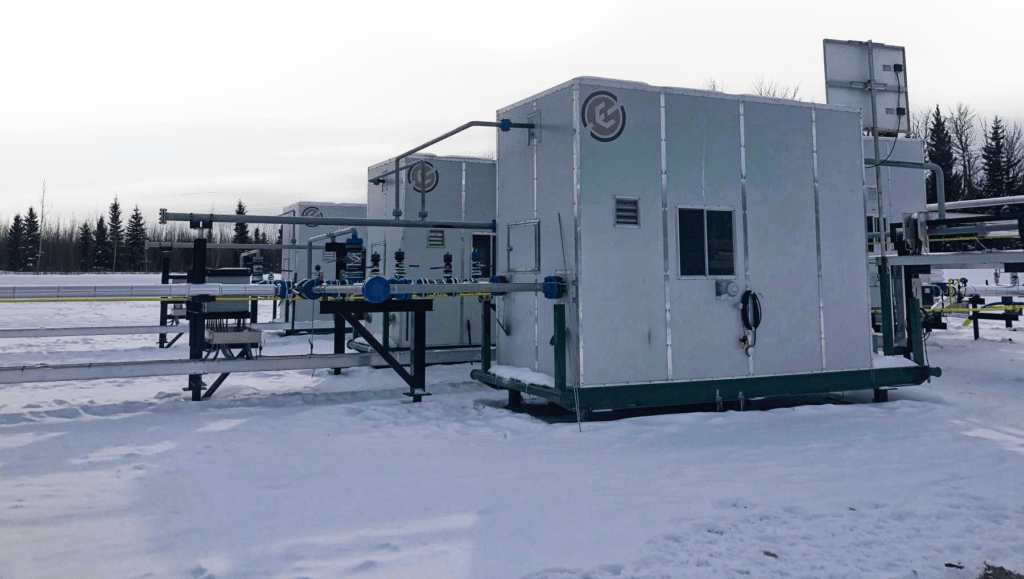

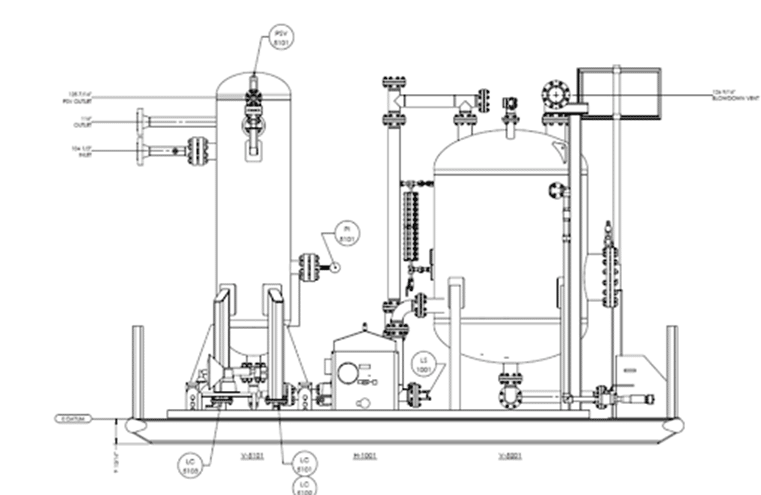

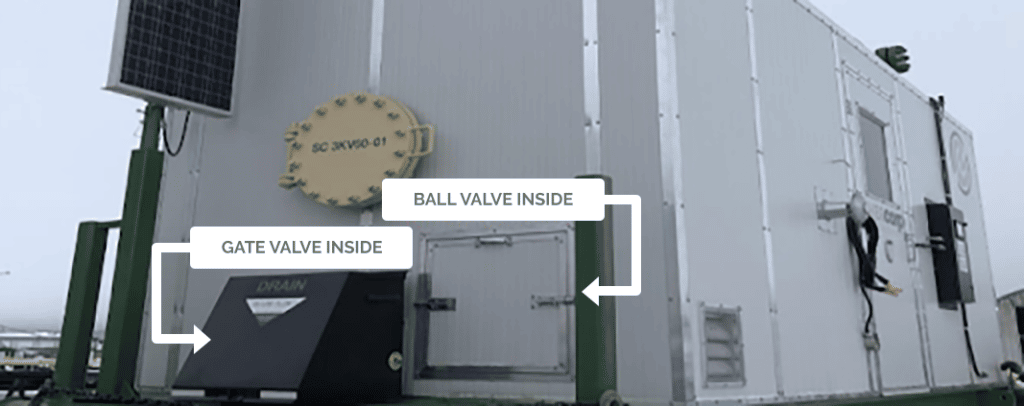

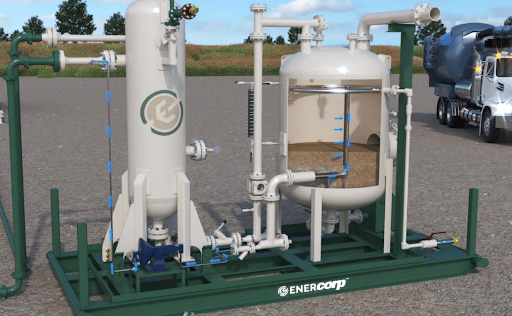

Our rental fleet in Canada is almost entirely made up of Combo units, with 3K and 5K pressure ratings. These have our Mojave Dual Sand Cyclone separation technology and a blowdown vessel with blowdown controls built into one skid. This skid is then enclosed in a winterized building — which protects the equipment from extreme weather.

Combo units are an all-in-one solution which integrate into the production facility so they are ready to operate. To reduce the risk of loss of containment, field connections and temporary piping are kept to a minimum. During rigup, this reduces the likelihood for missdirected flow.

In this rental model, we train the customers’ personnel on how to operate the equipment on a long-term basis. Many customers typically have our equipment on site for one year, while our longest deployment has been over five years. The EnerCorp rentals team is always available to help troubleshoot, maintain, and perform inspections on the equipment. We handle the delivery, set-up, and operational demonstrations. We also remain on call 24/7 throughout the equipment lifecycle.

Keeping ESG at the forefront of innovation

Due to the ESG regulatory environment in Canada, blowdown off gassing is most often required to be sent to a flare or vapor recovery unit (VRU). For Enercorp, it is easy to configure as each combo unit has its own dedicated enclosed blowdown vessel and a vent that can be connected to a flare or VRU.

This ensures that any well gas or flash gas from the blowdown is vented out to be reinjected, combusted, or flared, resulting in zero uncombusted methane emissions to the atmosphere.

The waste sand in the enclosed blowdown vessel is emptied via a truck out box accessible from outside the skid. It provides simple connections for a vac truck to connect and remove the solids. A sparge system to fluidize the sand is also common to make offloading easier.

As it is a regulatory requirement, and has been since 2006, EnerCorp has continued to perfect the technology and methods in this process. These can easily be transitioned to the United States as emissions and spill reduction become more of a focus in the country, especially in the area of production facility management. This is a step ahead of what most other flowback and production equipment fabrication providers currently do to meet ESG measures in the United States.

Environmental technology and processes

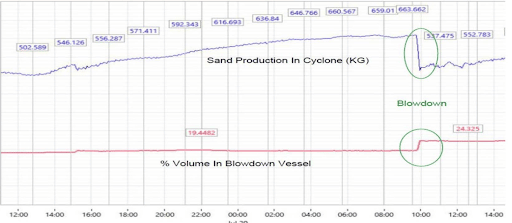

EnerCorp’s oilfield equipment units have SCADA functionality to monitor the technology remotely. We use a scale system to measure the weight of the Mojave Dual Sand Cyclone that can communicate through SCADA when the desander needs to be emptied of sand. Because everything is built onto a single skid, operation is simple and well laid out. Operators can open isolation valves and then blowdown with choke control, which forces the flow of sand and liquids into the blowdown vessel adjacent to the cyclone. EnerCorp also includes a site flow indicator, so that the operator can physically observe what they are blowing down and to ensure an efficient sand-evacuation process.

Many Canadian customers also use our fluid recycling system, which drains any liquids that get blown down to the blowdown vessel, and re-injects them back into the process flow. This effectively decreases the number of vac truck trips required to empty the blowdown vessel as the blowdown vessel is only full of the waste sand. Any liquids that would normally consume volume in the vessel are removed and re-injected into the well flow automatically. This process also helps to reduce emissions during the truck offloading operations.

While many operators in the oil and gas industry rent equipment, some prefer to own their own desanding equipment. EnerCorp’s production equipment fabrication department manufactures and sells standalone Mojave Dual Sand Cyclone, Sahara Advanced Sand Cyclone, Filtration, and Production Sand Separator packages. We can engineer and fabricate highly customized oilfield production equipment to meet every customer’s unique requirements. Our team offers assistance to the customer’s field personnel in terms of training, troubleshooting, inspections, and maintenance. All of the custom fabrication equipment always meets ESG regulations.

Ready for the next ESG challenge

With many years of experience meeting strict ESG regulations in Canada, EnerCorp is always prepared for the next ESG challenge. Whether in Canada or the United States, we are ready with product development specialists, field engineers, highly skilled operators, and highly engineered oil and gas equipment that is designed with ESG regulations in mind. From the equipment itself to the processes we use in the field, EnerCorp is committed to leading the charge in our industry and ensuring a cleaner and safer environment for future generations.

Want to get ahead of ESG regulations and learn more about our fit-for-purpose technology? Get in touch with EnerCorp today.

Share this Article